Geotechnical field testing

Site preparation

Level drill pad

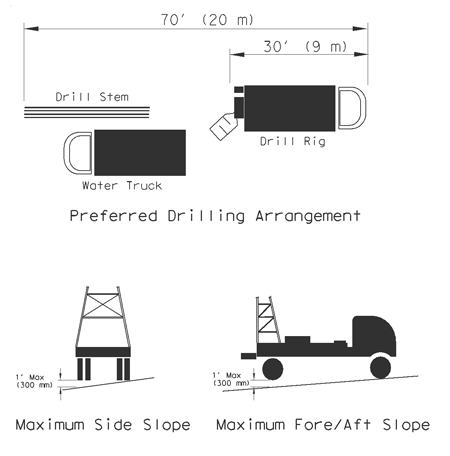

Prepare drilling sites before arrival of the drill crew. Note the kelly and mast of the drill rig are fixed to the truck bed and cannot swing.

Level the bed of the drill truck to drill a vertical hole. The truck is often equipped with hydraulic jacks that lift the truck off the ground to accommodate for uneven terrain. If the proposed drill site slopes steeper than 1 foot, prepare a 16-foot-wide by 70-foot-long work pad for leveling the rig and providing a safe work space for the crew.

For safety reasons, the crew is not allowed to use blocks under jacks to accommodate greater slope angles. The mud pan must be level or slightly down slope.

Before extensive site work, consult with drill crew performing the work for specific instructions. The figure below details the drill site requirements.

Overhead clearance

Overhead must be clear of obstructions, including the following:

- Trees cannot block the raising of the mast.

- It can be dangerous to work within a 25 to 35-foot proximity of an overhead power line, depending on the voltage. If you must work closer, contact the power company to cut the power or install insulating safety boots.

Underground utility locations

You must know the exact location of underground utilities including the following:

- High pressure gas lines.

- Water lines.

- Sewer and storm lines.

- Electrical and telephone conduits and cables.

Prior to drilling, the crew should perform site reconnaissance to inspect proposed locations, acknowledge the marked utilities, and make recommendations while on site, if needed. It is often possible to drill easy borings while preparing more challenging locations. Notify the contract engineer if the relocation of a boring is significant.

Access

Secure permission to enter private property before drilling.

Barge work

When a proposed bridge crosses large bodies of water, drill rigs on barges are used to obtain subsurface information for foundation design. Barge work is complex and expensive, so coordination with the drill crew and contractor should begin well before the start of field work.

Sampling

Dry barrel or single-wall sampler

Use the dry barrel (single-wall) sampler to obtain core samples for visual soil and bedrock classification and logging. The core sample obtained is generally in a disturbed condition due to the pressure applied when cutting the core and packing it into the barrel for recovery. The core is extracted from the barrel by water pressure.

When used for sampling in practically all foundation materials except very soft clay (muck) and cohesion less sand, the dry barrel sampler obtains a sample containing all components in the original formation. The amount and degree of disturbance depends upon the consistency and density of the material.

Although this method is called the dry barrel method, circulating water is often used. In hard formations, a smaller volume of water is circulated while cutting the core.

Diamond core barrel

Use diamond core barrels to obtain intact rock samples for field or laboratory tests and classification. The diamond barrel sampler has an inner and outer barrel. The inner barrel is slightly oversized with a spring-loaded core retainer at the bottom.

Push barrel or shelby tube sampler

Use the push barrel sampler (i.e. Shelby Tube Sampler) to obtain relatively undisturbed soil samples for field and laboratory tests and soil classification. The device consists of a thin-walled tube 24 to 36 inches long with one end sharpened to a cutting edge and the other end reinforced and designed for easy attachment to the drill stem coupling.

The thin-walled tube is steadily pushed into the formation with the hydraulic pull-down of the drill rig. This sampler recovers good undisturbed samples where it is adaptable, but its usefulness is limited to materials that it can be forced into and that have sufficient cohesion to remain in the barrel while the sampler is being withdrawn from the hole.

Use the device as follows in the steps below:

- Force sampler into formation with slow, steady push to about 12 to 24 inches deep.

- Rotate sampler several turns to shear off core at bottom before withdrawing it.

- Bring push barrel to surface.

- Detach barrel from coupling.

- Mount barrel on the hydraulic sampler extruder.

- Extrude core.

- Cut core into at least 6-inch lengths and place in thin plastic, such as food-storage bag, to retain moisture content. A better practice could be to first wrap the sample in aluminum foil, and then place in a food-storage bag.

- Place samples in carton box for transport to the laboratory for testing.

For samples of soft soil, sample disturbance can be a problem during transport to the testing location. To ensure minimum disturbance, support soft samples in their cartons. Fine dry sand poured around the sample in the carton provides excellent support during transport.

Store samples that are not immediately tested indoors, preferably a moist room with room temperature.

Wash sampling or fish-tailing

Of the many methods for penetrating overburden soil, consider only those that offer an opportunity for sampling and testing the foundation materials without excessive disturbance.

Do not use wash sampling or fishtail drilling unless absolutely necessary. Attempts to classify the soil materials by watching the wash water can lead to erroneous conclusions about the subsurface soil being penetrated.

Field testing

Texas Cone Penetration (TCP) Test

See Tex-132-E in the 100-E, Soils, & Aggregates Test Procedures manual.

Standard Penetration Test (SPT)

The SPT uses a 2-inch diameter split spoon sampler driven with a 140-pound hammer at a drop of 30 inches. The test is described in ASTM procedure D 1586. If TCP hammer weight (170 pound) and drop height (24 inches) are to be used for a modified SPT, indicate in the notes and drilling logs.

This SPT test is recommended mainly for granular soil but has been used in very hard cohesive soil. It cannot be used in rock.

It correlates roughly with the TCP test as follows:

- Clay: Ntcp = 1.5 Nspt

- Sand: Ntcp = 2 Nspt

Test correlations presented here are only for approximate evaluation of design adequacy from outside sources and not for normal foundation design work.

Observation wells and piezometers

Observation wells and piezometers are used to measure ground-water levels. Observation wells are essentially water wells and are sometimes pumped to determine the permeability of the soil to predict seepage volumes in excavations. Piezometers can be instruments which measure groundwater elevation.

For short-term observations of water levels, leave exploration core holes open for several hours to several days to monitor the ground-water level and note the depth to water in the hole. Cover the hole to protect people or livestock from injury. Note that open core holes will be susceptible to intrusion from surface runoff.

For long-term observations, install either observation wells or piezometers. Observation wells are most useful where the groundwater conditions are fairly stable, and in relatively porous soils or rock. They are simple to install and read, however they must be placed in a location where the top of the well is accessible. Piezometers are useful where access is difficult, since they may be read remotely. Piezometers are also more sensitive to groundwater changes in fine-grained soils. Many types of piezometers are available, with each having advantages and disadvantages. Consult with the designer regarding selection and installation of piezometers.

Typically, piezometers are used to evaluate ground-water levels in future depressed roadway sections and gauge ground-water effects on slope stability:

- Future depressed roadway sections: The construction and long-term performance of depressed roadway sections can be affected adversely by ground-water. The final installation may need special drainage features to control water inflows and provide a stable pavement section.

- Slope stability: Ground water affects slope stability by reducing the effective stresses in the soil through buoyancy. This applies to both side slope stability and bearing capacity of embankments and retaining walls.

Steps:

- Drill the hole with no water if possible. If not possible, drill with clear water. If hole stability continues to be a problem, add small amounts of drilling mud to the water.

- Place the assembled observation well piping into the hole. Either use a slotted screen, or drill holes in a section of the pipe and then wrap them with filter fabric. The upper sections of the pipe are not perforated.

- Place permeable granular media into the annular space between the pipe and core hole wall to all but the upper 5 to 10 feet of the hole. Use a fairly coarse sand or pea gravel to allow easy placement through water.

- Seal the remaining upper portion of the hole with grout or bentonite pellets to prevent surface flow infiltration. When using bentonite pellets in a dry hole, pour several gallons of water over the pellets for 10-15 minutes to start expanding the pellets to seal the hole.

- Finish the well in such a manner as to not be a hazard to the public. Typically, a flush mount cover when located in roadway or when concrete pad at the surface is created, or a stick-up cover when away from roadways. Use a locking cover if vandalism or tampering is possible.

Take a reading immediately and weekly thereafter until the water level stabilizes. Monthly readings thereafter are normally sufficient unless the site exhibits large fluctuations in readings.

Inclinometers

Inclinometers measure horizontal movements within a soil mass over time. The inclinometer is a sensitive device that measures deviations from vertical. Record these deviations at periodic intervals along a special casing grouted into a bore hole to determine the horizontal deviation of the casing from the bottom of the casing to the top.

The most common application is for monitoring slope or retaining wall failures to determine the failure plane depth and subsequent movement. Install inclinometer casing at several points in and adjacent to the failure, and use information from inclinometers in stability analyses. The bottom of the inclinometer casing must extend well below the failure plane for efficiency.

Take an initial set of readings immediately after casing installation to establish the baseline reading. Compare all subsequent readings to the baseline to determine direction and amount of movement. Base frequency of readings on the rate of failure of the slope or retaining wall.

The installation of casing, operation of the inclinometer, and data reduction is quite complicated. Consult TxDOT’s Bridge Division geotechnical engineers if inclinometer measurements are required.

Classification

Bedrock classification

- Igneous - granite, basalt

- Metamorphic - gneiss, schist, slate, marble

- Sedimentary: Clastic - shale (claystone), siltstone, sandstone, breccia, conglomerate, limestone, glauconite limestone, dolomite, lignite

- Sedimentary: Non-Clastic - chert, iron deposits, gypsum, halite, peat, coal

Soil classification

- Cohesive - Clay (CH/CL/CL-ML)

- Cohesionless - Silt (ML), sand (SC/SW/SP/SM/SP-SM/SC-SM), gravel (GW/GP/GC/GM/GP-GM/GP-GC)