13.7 Alternatives Analysis

13.7.1 Overview

This section provides guidance on developing alternatives analyses in microsimulation models. When comparing potential solutions, a modeler is recommended to develop a model for the existing conditions, future conditions without improvements (no-build), and the proposed improvements (build alternatives). Comparing the MOEs selected across all models will help in the selection of the locally preferred alternative.

Chapter 8

of this manual provides more information on analyzing alternatives and additional criteria to consider13.7.2 Number of Simulation Runs

Simulation models use numerous Random Seeds to demonstrate natural variations in driving behaviors and vehicle entry into the network. To confirm validity of a model, it is recommended that the number of simulation runs is large enough where an atypical run has minimal effect on the sample average. Simulation runs are typically determined for every model being tested. Per FHWA guidance, the following formula is used to calculate the necessary minimum number of simulation runs with a 95% confidence level. A 95th-percent confidence interval is typically used, but may not be the best value for every analysis:

where:

N: Minimum number of simulation runs

x̄

: Mean of observations𝑠: Standard deviation of observations

n: Number of observations

tn

−1,95% : t statistic for n-1 degrees of freedom and 95% confidence level e: tolerance error percentage

To use this equation, first select a preliminary number of model runs for which the initial mean and standard deviation are derived. These initial values are then used in the equation to determine the minimum number of simulation runs. If the calculated number of simulation runs is unreasonably high, first confirm there are no significant deviations in any of the simulation runs that would skew the calculation. After that, if the calculated number of simulation runs is still high, the cap is 25 runs per project. Generally, the minimum number of simulation runs is 10.

13.7.3 No-Build and Build Model Development

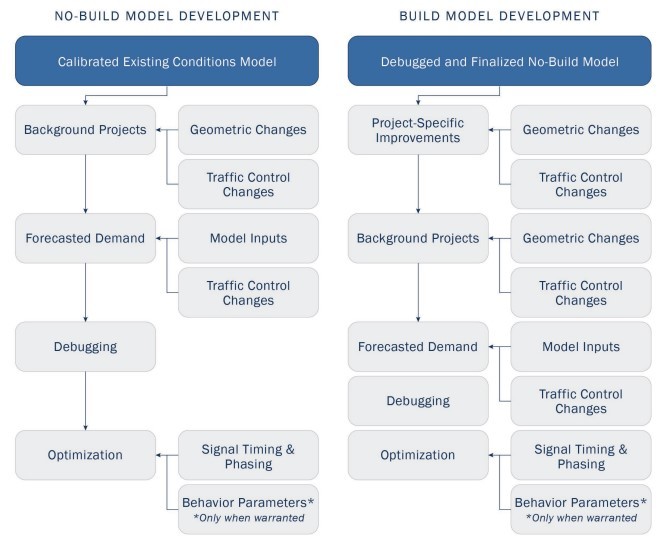

After developing, debugging, and calibrating an existing conditions model, no-build and build (alternative) models are created. These models are created from the existing model. No-build and build conditions can include optimizing existing signal timing plans; however, adding or modifying signal timing phases is considered an operational improvement alternative. There can be minimal changes to calibrated parameters in the model when developing future year models. However, use engineering judgement to confirm that new geometries and conditions in the future build years are represented realistically in the microsimulation model. Some elements maintained between models are driving behaviors, terminal conditions, and lane change distances. See for a flowchart of the different aspects of both no-build and build model development.

13.7.4 Future Year Models

13.7.4.1 Geometry

In developing a future year model, other planned projects are considered as they may impact traffic in the study area. If there are geometric changes to the study area determined from planned projects in TxDOT’s Project Tracker or the Unified Transportation Plan (UTP), implement those changes by following the development guidance used to develop the existing model. Planned multimodal improvements are also included unless otherwise agreed upon.

13.7.4.2 Forecasted Demand

Future traffic demand is used to analyze planned projects in the future year models. Further guidance on the process of traffic forecasting is provided in

Section 3.3

of this manual. Traffic volumes are projected and balanced for the new conditions under the future year models to reflect the changes. Traffic volumes, classification data, vehicle characteristics, and traffic patterns are examples of inputs that are modified based on forecasted demand.13.7.4.3 Debugging

Future year models are recommended to follow the same debugging process as outlined in

Section 13.4.8

. Use engineering judgement when debugging.13.7.4.4 Validation

Validation demands data, which does not exist for future year analyses. Nevertheless, parameters are updated when necessary. Signal timing and phasing are changed to accommodate demand and new geometry improvements. Driving behavior can only be adjusted in future conditions when roadway geometry or traffic control changes drastically. The HCM 7th Edition provides guidance on adjusting capacities to accommodate CAVs. Guidance on CAVs in the HCM 7th Edition can be found in various chapters. For information on modeling autonomous vehicles, refer to the respective microsimulation software user guide.

13.7.5 Future No-Build Models

No-build models represent future traffic conditions without the implementation of considered improvements or alternatives. They are the baseline for future model comparisons. These models are created from a calibrated existing model and include any committed projects. These models sometimes include other planned projects that impact traffic in the proposed project study area.

13.7.6 Build (Alternative Design) Models

Build (alternative design) models are developed to represent one or more design alternatives for evaluation. These build models include exclusive improvements or a combination of improvements. These are created from the no-build model for the same future year.

illustrates the process for creating the No-Build and Build (alternative) Models.

Figure 13-8: No-Build and Build Model Development