Profiled Thermoplastic

Profiled thermoplastic markings are sprayed or extruded thermoplastic markings that are constructed with an alternating elevated and recessed profile. The purpose of the profiled pattern is to provide nighttime retroreflectivity under wet conditions, and in cases where the profiles are large enough, a rumble effect can be felt when driving over the markings. The elevation-recession pattern may be placed using one of many methods. The two most popular methods are inverted-profile markings and raised-profile markings. Descriptions of each follow.

Inverted-Profile Markings.

Inverted-profile markings are created by a cog rolling over wet thermoplastic giving the line a corrugated appearance. Figure 2-12 shows a typical inverted-profile pavement marking.

Figure 2-12. Typical inverted-profile thermoplastic marking (profile view).

Raised-Profile Markings.

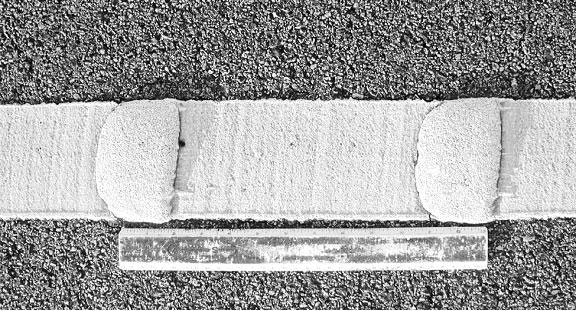

Raised-profile markings are created by extruding a thermoplastic marking of normal thickness with a raised thermoplastic “bump” (approximately 300 mil) at uniform spacing (often 3 ft). Figure 2-13 shows a typical raised profile pavement marking.

Figure 2-13. Typical raised-profile thermoplastic marking (overhead view).

Performance and Use.

Profiled thermoplastic generally performs well on all types of pavement surfaces. These markings often cost significantly more than standard thermoplastic (up to six times as much), but are often warranted by the contractor. The good performance may be attributed to the stringent contractor-supplied on-site inspection provided during most applications.It should be noted that profiled markings are not necessarily limited to thermoplastic materials. Profiled markings may be constructed from materials other than thermoplastic as long as the same visual-tactile benefit is provided.