Contrast Markings

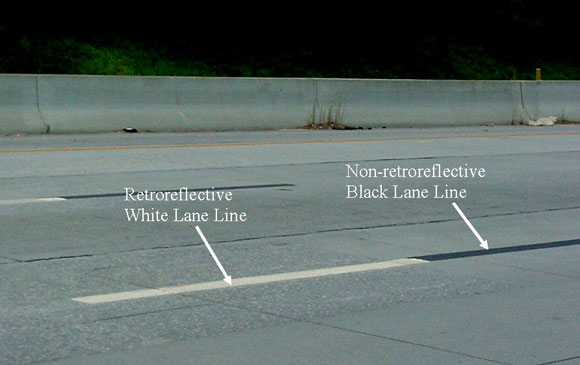

Human vision is tuned to detect edges of contrasting color or brightness. Many concrete and heavily oxidized asphalt pavements are so light in color that during the day, white pavement markings appear to blend in with the pavement surface. To improve the visibility of pavement markings on light-colored pavements, markings are often applied over the top of a compatible black marking material. The underlying black material is usually applied at a greater width than the actual marking (minimum 1 inch) so that it provides a contrasting border around the marking. Contrast markings on white lane lines can also be applied with longitudinal leading or tailing sections of black material at least 12 inches in length. While many materials may be used as contrast markings, compatibility between the top and bottom materials must be ensured. Figure 2-14 shows a typical contrast pavement marking for a lane-line application, and Figure 2-15 shows a lead-lag type of contrast marking application.

Figure 2-14. Typical bordered-contrast pavement marking for lane line.

Figure 2-15. Typical contrast pavement marking for lane (line lead-lag layout).

Contrast markings are suitable for use at any location where the visibility of the pavement markings is poor, usually due to a light-colored pavement surface. Because of the increased expense for application of contrast markings, they are often used only for white lane lines on divided highways with light-colored pavements.