Emulsified Asphalt

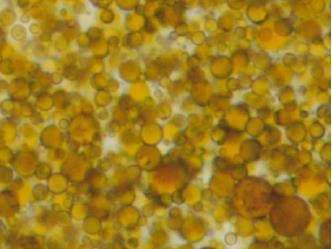

Emulsified asphalt consists of asphalt cement droplets suspended in water (Figure 3-1). This dispersion, under normal circumstances, would not take place, since oil and water do not mix. If an emulsifying agent is added to the water, the asphalt cement will remain dispersed.

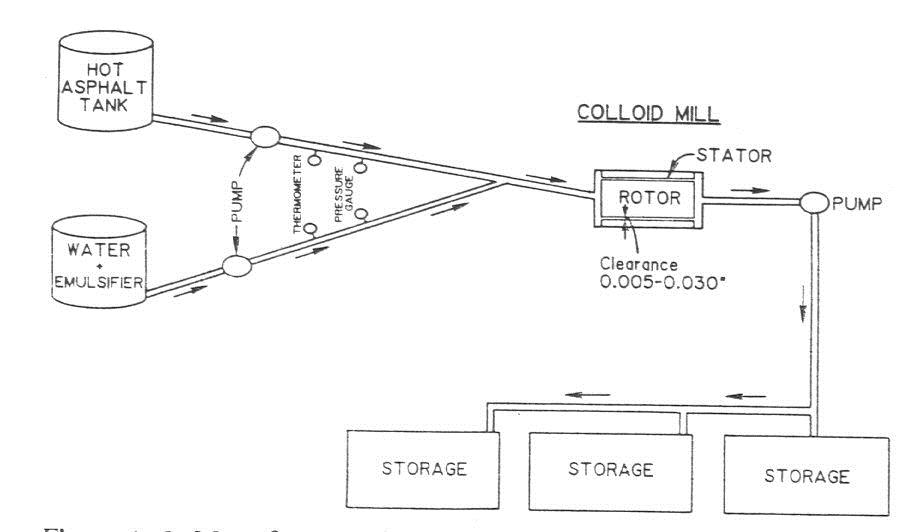

In the production of asphalt emulsion, water is mixed with an emulsifying agent and is pumped to a colloid mill along with asphalt (Figure 3-2). The colloid mill breaks the asphalt up into tiny droplets less than 5 microns in diameter. The emulsifying agent migrates to the asphalt-water interface and keeps the droplets from coalescing, because the asphalt droplets all carry the same electric charge. The emulsion is then pumped to a storage tank.

Figure 3-1. Greatly magnified image of emulsified asphalt.

Emulsions are produced for ease of application. Emulsions enable much lower application temperatures to be used. Application temperatures range from 120°F to 160°F. This is much lower than the 275°F to 350°F used for asphalt cements. The lower application temperatures will not damage the asphalt and are much safer for field personnel.

Figure 3-2. Manufacture of emulsified asphalt.

After emulsion and aggregate have been applied to the road surface, the emulsion “breaks” leaving the asphalt cement holding the aggregate. The rate at which the asphalt globules separate from the water phase is referred to as the “breaking” or “setting” time. The rate of breaking is controlled primarily by the specific type and concentration of the emulsifying agent used, as well as atmospheric conditions.

The fact that different aggregate types have different rates of absorption means that breaking is also related to the relative absorption characteristics of the aggregate used. Those with higher absorption rates tend to accelerate the breaking of the emulsion due to the more rapid removal of water.

When the emulsion and the aggregate are oppositely charged, the initial break develops through the electrochemical charge between the emulsion and the aggregate. The main bond of strength between the asphalt film and the aggregate comes after the loss of water. The breaking or setting rate may be affected by the following factors:

- porosity of the aggregate

- moisture content of the aggregate

- weather conditions (temperature, humidity, wind)

- emulsion and aggregate temperature

- mechanical forces (traffic, rolling)

- cleanliness of aggregate

- type and amount of emulsifying agent

- intensity of charge on aggregate versus intensity of emulsifier charge.

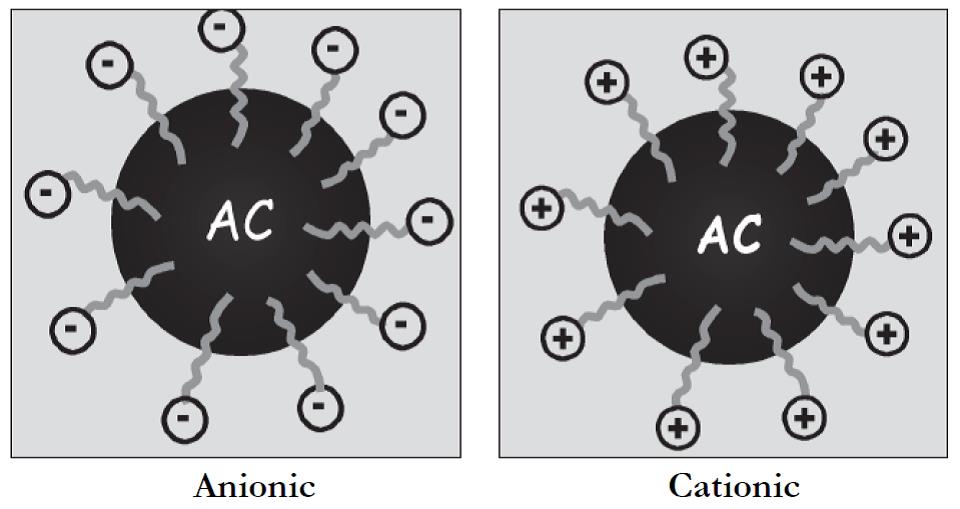

Asphalt emulsions are divided into three categories: anionic, cationic, and non-ionic. In practice, only the first two are used for surface treatments and seal coats. The anionic and cationic classes refer to the electrical charges surrounding the asphalt particles. Cationic emulsions have a positive (+) electrical charge and anionic emulsions have a negative (-) electrical charge. Aggregates for use with emulsions should not be precoated because the precoating inhibits the chemical break, absorption, and adhesion of the emulsion to the rock. In general, cationic emulsions will break and set more quickly than anionic emulsions. In high humidity or cooler weather, cationic emulsions can break and set more quickly than anionic emulsions due to the electrochemical reaction between the aggregate and the binder in addition to evaporation of the water. Anionic emulsions tend to work well in low humidity or warm weather conditions.

Figure 3-3. Basic emulsion types.

Emulsions are named to describe their type, speed of break, and viscosity. A designation of “C” is used for cationic emulsions. Emulsions not using a “C” are anionic. Speed of break is designated by “RS” for rapid set, “MS” for medium set, and “SS” for slow set. The residue viscosity is designated by a number, usually a “1” or “2.” The “1” is a low viscosity emulsion used for such applications as fog sealing or cold weather applications where we want the emulsion to flow into cracks and crevices. The “2” is a high viscosity emulsion used for such applications as seal coats and surface treatments. If the number is followed by the letter “H,” the emulsion has a harder base asphalt. If the number is followed by the letter “P,” the emulsified asphalt contains a polymer. For example, CRS-2P is a cationic, rapid setting, high viscosity emulsion with polymer.

High-float (HF) emulsions, such as HFRS, have a quality that permits a thicker asphalt film on the aggregate particles and prevents drain-off of asphalt from the high points of the road surface.

Some properties of emulsions can be enhanced by the addition of polymers. Advantages of polymer-modified emulsions are:

- To increase the viscosity of the residual asphalt and thus minimize bleeding

- To maximize aggregate retention

- To enhance flexibility over time.