Distributor Heating System

Asphalt temperature is a critical factor in the success of a seal coat/surface treatment. To maintain a constant temperature, a proper heating system is necessary.

Burners.

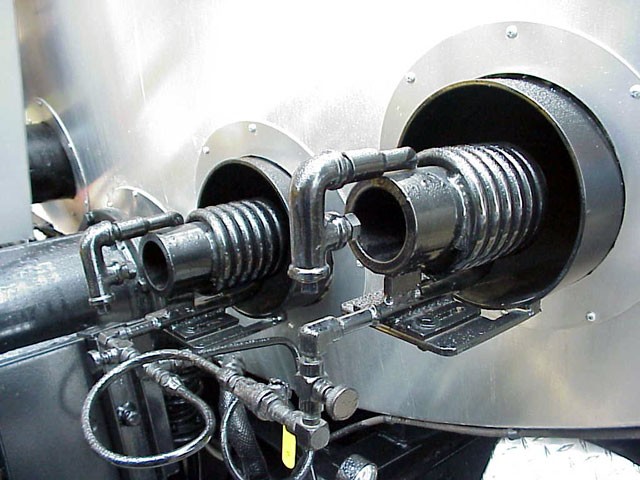

Depending on the make and size of the distributor, either one or two propane or diesel fired burners are used. The burners are mounted on the platform at the rear of the tank and are positioned so the flame is directed into the flues that pass through the tank. Figure 7‑7 shows a typical configuration.

Figure 7-7. Burner Configuration at Rear of Tank.

Heating.

The need for heating will depend on the following:- Type of asphalt binder being used

- Ambient temperature

- Length of time the binder is in the distributor before being sprayed on roadway

- Whether the distributor is filled directly from heated storage tanks or has been hauled some distance in an insulated transporter.

Most emulsions used for seal coats are applied at 120°F to 160°F. When using asphalt cement, application temperatures may range from 275°F to 375°F. Application temperatures for cutback asphalts may range from 125°F to 275°F. Cutbacks should be shot 25°F to 50°F below their respective flash point. For each binder type, refer to Item 300, Asphalts, Oils, and Emulsions, for correct heating and application temperatures.