Section 1: Modified Kearby Design Method

General

The design method described in this section is based on a modification of the original Kearby method and was first recommended to TxDOT by Texas Transportation Institute in 1981 (Epps et al., 1981). It is still the method most commonly used by TxDOT today. A formal design method such as this can effectively serve to guide inexperienced personnel through the “art” of seal coat design and to train personnel including inspectors, designers, and laboratory personnel. Correction factors for binder application rates for varying conditions including traffic and surface condition may be developed for conditions unique to a district and will ensure a much faster learning curve for inexperienced personnel. Examples of some adjustment factors, which were developed by the Brownwood and Abilene districts, are shown in

. Sample calculations are shown in

.

A design method such as described herein should be used to determine initial binder and aggregate application rates, but it should not take the place of good engineering judgment. Field conditions will require the adjustment of both binder and aggregate rates.

Laboratory Tests

This design methodology requires the knowledge of some physical

characteristics of the aggregate, such as unit weight, bulk specific

gravity, and the quantity of aggregate needed to cover one square yard

of roadway. Once the contractor has identified the aggregate to

be used for the seal coat, samples of the stockpiled materials should

be obtained to perform the following laboratory tests:

- Dry Loose Unit Weight—TxDOT Test Method Tex-404-A

- Bulk Specific Gravity—TxDOT Test Method Tex-403-A for all natural aggregate and Tex-433-A for lightweight aggregates

- Board Test—described below.

Determining Design Rates

Aggregate Spread Rate.

The Board Test is used to find the quantity of aggregate on a board of known aggregate such that full coverage, one stone in depth, is obtained. A one-half square yard area is a convenient laboratory size. The weight of aggregate applied in this area is obtained and converted to units of pounds per square yard. Good lighting is recommended and care should be taken to place the aggregate only one stone deep. The quantity of aggregate needed to cover one square yard of roadway can also be determined in terms of volume as shown in Equation 4.1.

Equation 4-1..

where:

- S = quantity of aggregate required in square yards per cubic yard (SY/CY);

- W = dry loose unit weight in pounds per cubic foot (lbs/CF); and

- Q = aggregate quantity determined from the board test (lbs/SY).

Asphalt Application Rate.

The asphalt application rate for asphalt cement can be obtained from Equation 4.2 once the aggregate properties and existing roadway conditions are known.

Equation 4-2.

where:

- A = asphalt rate in gal/SY at 60°F

- E = embedment depth calculated using Eq. 3

- G = dry bulk specific gravity of the aggregate

- T = traffic correction factor (see Table 4-1)

- V = correction for surface condition (see Table 4-2).

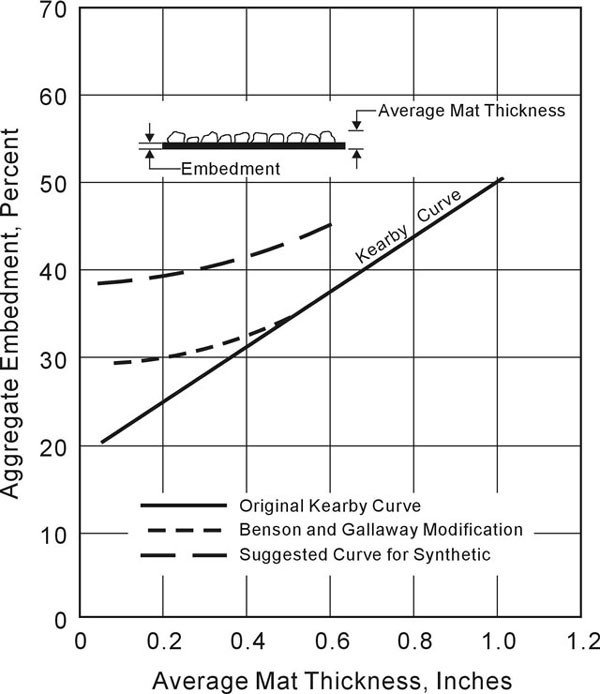

Equation 4-3.

where:

- d = average mat depth in inches, as calculated from Eq. 4

- e = percent embedment expressed as a decimal from Figure 4‑1.

Equation 4-4.

where:

- Q = aggregate quantity determined from the board test in lbs/SY

- W = dry loose unit weight in lbs/CF.

Relation of Percent Embedment to Mat Thickness for Determining Quantity of Asphalt. (After Epps et al., 1981)Table 4-1. Asphalt Application Rate Correction for Traffic.Traffic – Vehicles per day per laneTraffic Correction Factor (T)>1000500-1000250-500100-250<100Traffic Correction Factor (T)1.001.051.101.151.20Table 4-2. Asphalt Application Rate Correction for Existing Pavement Surface Conditions.Description of Existing SurfaceCorrection for Surface Condition (V), gal/SYFlushing, slightly bleeding surface-0.06Smooth, nonporous surface-0.03Slightly porous, slightly oxidized surface0.00Slightly pocked, porous, oxidized surface+0.03Badly pocked, porous, oxidized surface+0.06These surface conditions may vary throughout the project, and adjustments should be made accordingly.Adjustment for Asphalt Emulsions or Cutbacks.For emulsions, the application rate (A from Eq. 2) should be increased to take into account the water in the emulsion. Therefore, Equation 5 is presented to determine the recommended emulsion application rate. In theory, the asphalt cement rate from Eq. 2 can be converted to the required emulsion rate by dividing this amount by the residual asphalt present in the emulsion. However, field experience shows that if this value is utilized, flushing is likely to occur. Therefore, the recommended emulsion application rate is adjusted as shown below:

Relation of Percent Embedment to Mat Thickness for Determining Quantity of Asphalt. (After Epps et al., 1981)Table 4-1. Asphalt Application Rate Correction for Traffic.Traffic – Vehicles per day per laneTraffic Correction Factor (T)>1000500-1000250-500100-250<100Traffic Correction Factor (T)1.001.051.101.151.20Table 4-2. Asphalt Application Rate Correction for Existing Pavement Surface Conditions.Description of Existing SurfaceCorrection for Surface Condition (V), gal/SYFlushing, slightly bleeding surface-0.06Smooth, nonporous surface-0.03Slightly porous, slightly oxidized surface0.00Slightly pocked, porous, oxidized surface+0.03Badly pocked, porous, oxidized surface+0.06These surface conditions may vary throughout the project, and adjustments should be made accordingly.Adjustment for Asphalt Emulsions or Cutbacks.For emulsions, the application rate (A from Eq. 2) should be increased to take into account the water in the emulsion. Therefore, Equation 5 is presented to determine the recommended emulsion application rate. In theory, the asphalt cement rate from Eq. 2 can be converted to the required emulsion rate by dividing this amount by the residual asphalt present in the emulsion. However, field experience shows that if this value is utilized, flushing is likely to occur. Therefore, the recommended emulsion application rate is adjusted as shown below:

Equation 4-5

where:

- Arecommended = recommended quantity of emulsion

- A = asphalt application rate from Eq. 2

- K = seasonal adjustment factor as shown below

- Atheoretical = theoretical quantity of emulsified asphalt, (A/R).

- where:

- R = percent residual asphalt in the emulsion expressed as a decimal. Check with supplier to determine percent residual asphalt content of emulsion.

- K = 0.60 for spring construction

- K = 0.40 for summer construction

- K = 0.70 for fall construction

- K = 0.90 for winter construction.

- K = 0.70 for spring construction

- K = 0.60 for summer construction

- K = 0.80 for fall construction

- K = 0.90 for winter construction.

The K factors have not been verified by extensive controlled field experiments and therefore should only be used as a guideline.

Refer to Appendix B for a sample calculation.