6.2 Fixed-form Paving

Although not used very often in Texas, paving machines that ride on forms are still in use. Paving machines that use steel wheels to ride on paving forms are very heavy machines, almost comparable to a slip-form paving machine without the drive tracks. To prevent sagging under the weight of this machine, the forms need to be uniformly supported on a very firm base.

Smaller paving machines, such as the Clary, have three long steel roller tubes that extend across forms in both directions. The rollers propel and screed the concrete to the level of the forms. This type of paving machine is still seen on small and irregular placements, such as ramps and turnarounds. It is limited to smaller productivity and narrower placements.

Another type of paving machine that has actually been used in recent years on main lane urban freeways is the Bidwell, a machine that is more commonly seen on bridge deck construction. This machine rides on forms or steel pipes. It is characterized by a truss extending across the forms with a suspended longitudinal screed roller that moves transversely across the pavement. An auger mounted on the front end of the roller screed spreads the concrete, and the roller screed smooths the surface.

Neither the multiple roller-type paver or the bridge-type machine enjoy a reputation for producing a very smooth riding surface and are unlikely to be seen on a pavement surface where a ride specification with bonus/penalty is in effect. Productivity is also relatively low for both types of machines.

Fixed-form paving is a form of concrete pavement construction where fixed forms are used to hold the concrete in place at the proper grade and alignment during construction. This type of paving is different from slip-form paving, which utilizes the forms of the slip-form paving machine to form or mold the concrete in place at the proper grade and alignment, in lieu of fixed forms, during paving. In general, fixed-form paving is not as productive as slip-form paving because of the difference in the efficiency of the placing, spreading, and finishing operations with form riding equipment. In addition, it takes time and effort to set and remove forms before and after paving. However, fixed-form paving is more applicable than slip-form paving in certain situations, such as ramps, blockouts, small paving areas, or where slip-form paving is not feasible or economical. Most of the main lane concrete paving in TxDOT projects is done by slip-form paving. Usually, only minor portions of the concrete paving are done by fixed-form paving.

To facilitate the placing, spreading, consolidation, and finishing operations, concrete used for fixed-form paving usually has more workability or higher slump than the concrete used with slip-form paving.

6.2.1 Forms

A key element in fixed-form paving for constructing a smooth concrete surface is the form. Typical forms have the following characteristics:

- Most of the forms are made of metal with a minimum thickness of at least 0.2 in. and are 10 ft. long.

- The height of the forms determines the slab thickness.

- The bases of the forms are wide and flat. These wide and flat bases provide stability of the forms while in place.

- Flange braces extend outward from the base not less than 2/3 the depth of the form.

The final grade and smoothness of the concrete surface is determined, to a large extent, by how secure and how close the forms are set to the final grade and alignment lines. One of the most important requirements of the forms is to provide stability while concrete is being placed. Unstable forms will cause irregularities in the finished concrete pavement. The top and the face of the forms should be as flat as possible. A straightedge or stringline can be used to check for variance. Forms must be free from detrimental kinks, bends, or warps that could affect ride quality or alignment. The forms should allow for tightly locking the ends of adjacent form sections. The ends of the forms should be flush when they are in position. All forms must be cleaned and oiled before use.

6.2.2 Setting Forms

A survey line is established to facilitate setting forms at proper grade and alignment. Form setting is a critical construction operation since the final grade and smoothness of the pavement surface depends, to a large extent, on how accurately the forms are set to line and grade and how well and uniformly the forms are supported by a firm foundation.

The finished smoothness of the pavement depends on the care with which the forms are set and maintained because the finishing equipment rides on the forms. Proper alignment and elevation of the forms will contribute to a smooth pavement. It is important to provide a firm and level foundation under all forms. Figure 9-21, Figure 9-22, Figure 9-23, and Figure 9-24 illustrate the process of form setting.

Once the forms have been set, they are checked for overall alignment and tolerance before any paving takes place. If any form section is out of line, it needs to be corrected immediately. Joints between forms must be tight and smooth. Specification Item 360 requires that the contractor provide metal side forms of sufficient cross-section, strength, and rigidity to support the paving equipment and resist the impact and vibration of the operation without visible springing or settlement.

Figure 9-21. Forms ready for setting.

Figure 9-22. Using jackhammer to set staking pin.

Figure 9-23. Staking pin.

Figure 9-24. Side forms used for paving.

The preferred depth of the form shall be equal to the required edge thickness of the pavement. Forms with depth greater or less than the required edge thickness of the pavement can be used if the difference between the form depth and the design pavement depth is not greater than 2 in., and:

- forms of a depth greater than the pavement edge thickness may be used if the supporting material is planed to construct a form trench;

- forms of a depth less than the pavement edge thickness shall be brought to the required edge thickness by securely attaching metal strips or wood shims of approved section to the full width and length of the base of the form, as shown in Figure 9-25. Use grout to fill the gap with wood shims to establish grade.

Figure 9-25. Side form.

6.2.3 Checking Forms

Unlike a slip-form paving operation, where the thickness of concrete pavement can be adjusted for “knots” or rises in the base to maintain proper thickness, the thickness of concrete pavement is established by the height of the side forms. That is, side forms that are 8 in. tall will produce a concrete pavement that is at least 8 in. tall only if the base between the two forms does not have an area that is above the level of the bottom of the forms. To check that there are no bumps in the base, a “scratch” template may be used.

The scratch template is typically a lightweight truss that is supported on the side forms by wheels and has long metal tines spaced about a foot apart that extend down from the truss for the thickness of the concrete pavement. The scratch template is moved along the side forms. If the tines on the scratch template come in contact with the base and “scratch” the surface, that would indicate an area with a rise in the base and where the concrete pavement would have insufficient thickness. If there is a high spot in the base, then that area needs to be milled down, or more commonly, the side forms need to be shimmed up to achieve proper concrete pavement thickness. Base planers were used in the past with side form paving to excavate excess base material. These planers were suitable for use on non-stabilized base materials. Any milling of stabilized base should be approved by the engineer to ensure that no damage to the base or deficient base thickness result.

6.2.4 Paving Operations

As with any paving method, it is important that the concrete be discharged, consolidated, and finished to provide optimum ride quality and long-term performance. Equipment used for placing and finishing concrete in fixed form paving varies substantially from project to project, and detailed descriptions of the placing and finishing operations are not provided in this document.

One of the key elements in fixed-form paving is to maintain a consistent and uniform head of concrete in front of the strike-off screed. The strike-off screed used in fixed-form paving is lighter than the one used in slip-form paving, and too much variation in the head of concrete will result in reduced smoothness of the concrete surface. A head of concrete that does not run over forms or the screed works best. Also, steady machine progress improves pavement smoothness, and concrete should be delivered to ensure steady machine progress.

Finishing operations such as floating, burlap/carpet drag, tining, and curing operations are similar to those in slip-form paving, and they are described under “Slip-form Paving.”

Figure 9-26, Figure 9-27, and Figure 9-28 show how a vibrating screed is pulled forward with a winch at each end of the screed connected to a cable hooked ahead of the screed. A manually operated finishing screed shall be a strike template and a tamping template or a vibratory screed with adequate length to cover the width of the slab.

Figure 9-26. Vibrating screed.

Figure 9-27. A Clary or roller screed.

Figure 9-28. Knock down the ridge of mortar formed by the Clary screed.

When the concrete is setting up on the screed and the screed needs to be cleaned, have the contractor move the screed ahead of the concrete so that cleaning water does not fall on the plastic concrete. Figure 9-29 shows the cleaning of the screed between haul trucks.

Figure 9-29. Cleaning screed between haul trucks.

For finishing, texturing, and curing operations, please refer to “Slip-form Paving” below.

6.2.5 Removing Forms

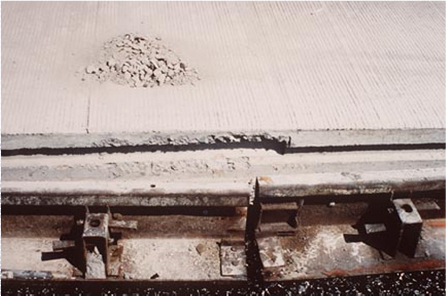

Forms can be removed as early as practical without damaging the concrete. In most instances, forms can be removed within 6 to 8 hr. after concrete placement. The forms shall be carefully removed in such a manner that minimal or no damage will be done to the edge of the pavement. All damage resulting from this operation and any honeycombed areas shall be repaired with a mortar mix within 24 hr. after form removal. Immediately after removing the side forms from the concrete pavement, apply membrane cure to all concrete surfaces not previously treated. Forms should be cleaned right after removal. If not, they become difficult to clean. Figure 9-30 shows removed side forms.

Figure 9-30. Removed side forms.