6.5 Finishing Operations

6.5.1 Sealing the Surface of the Concrete

To close all surface openings and produce a uniformly smooth and flat surface, the plastic concrete behind the screed is either floated or straightedged, or both.

6.5.2 Floats

A float may be used only when using a finishing machine. Figure 9-50 shows an example of tube floats. Tube floats are pulled back and forth in the longitudinal direction. Notice that each tube float is suspended and pulled by chains. The tube floats are set at 60 degree angles to the pavement’s centerline. The leading end of the tube float may be on either the inside or outside of the pavement. The tube floats must extend across the entire width of the pavement being placed. For wide concrete placements, more than one tube is used.

Figure 9-50. Tube floats.

Tube float machines must have spray nozzles to provide a fine, light fog mist to the concrete surface just ahead of the tubes.

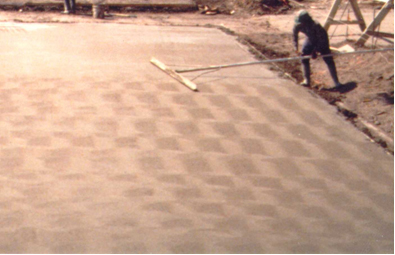

A longitudinal float, also called auto float, slides back and forth in the transverse direction. An example of a longitudinal float is shown in Figure 9-51. Notice the surface marks left by the float.

Another type of float is the drag float, an example of which is shown in Figure 9-52. Because a drag float is heavier than a tube float or a longitudinal float, the drag float applies greater surface pressure, making it more effective at smoothing out a knot or bump in the plastic concrete. A drag float needs to be more effective because it only makes a single pass across the plastic concrete.

Figure 9-51. Longitudinal float.

Figure 9-52. "V" shaped drag float pulled by paver.

When using a drag float, be careful that the float does not slowly slide to the downhill side when paving a crowned or superelevated section.

When the float cannot reach to the edges, the edges are floated with hand trowels. Such a process is shown in Figure 9-53.

Figure 9-53. Hand trowel.

Care must be exercised while floating to avoid distorting the surface. A bull float (Figure 9-54) can produce a depression if excessively used in one spot. Longer bull floats will produce better results. Bull floating should be limited to small areas and should not be used to float the entire surface. Avoid using a bull float, if possible.

Figure 9-54. Bull float.

6.5.3 Straightedge

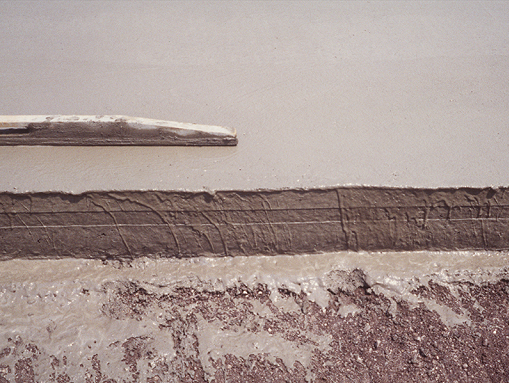

A straightedge is a 10-ft. or 15-ft. long, steel or magnesium, square tube, which contacts the concrete surface. An illustration of straightedge finishing is shown in Figure 9-55 and Figure 9-56. A straightedge flattens the concrete surface and in the case where floats were not previously used, can close surface tears produced by a screed. A straightedge is better at flattening surface bumps and seams than a float, but using a straightedge takes longer than floating because it cannot be mechanized. The straightedges should be parallel to the centerline of the pavement.

Figure 9-55. Straightedge finishing.

Figure 9-56. Straightedge finishing behind a longitudinal float.

Notice in Figure 9-56 that the surface no longer shows the irregularities left by the longitudinal float.

6.5.4 Bleed Water and Free Surface Water

Finishing should be held to a minimum during the period of greatest bleeding since working the surface in the presence of excess water leaches out a portion of the cement and produces low-strength surface mortar. The use of supplementary cementitious materials, such as fly ash and slag cement, reduces bleeding water.

Under calm wind and high relative humidity conditions, the concrete pavement should provide enough bleed water that little or no water needs to be added to float and finish the concrete surface. Under very dry conditions or when there is a strong breeze, the bleed water may evaporate rapidly before floating can be performed. A fine mist of water may be used to reduce the loss from evaporation, but never to form slurry. The fine mist should come from a misting nozzle mounted on a pipe frame that is not pointed directly at the pavement surface.

Water is not allowed to be applied from a nozzle or thumb over a garden-type hose as shown in Figure 9-57. Adding water to the surface makes the finishing easy to perform. However, this practice dilutes and washes away the surface mortar, resulting in poor performance of concrete pavement in terms of skid resistance, scaling, and durability.

If excessive mortar slurry is present during finishing operations (see Figure 9-58) without the addition of water, this generally indicates an issue with the concrete mix. Batch plant operations should be reviewed to correct this situation.

Finishing operations should not be conducted when free water is on the surface of the concrete. Finishing with water on the surface will cause the cement at the surface of the concrete to become diluted or even washed away as shown here. Wait until the water evaporates before continuing with the finishing.

Figure 9-57. Unacceptable - Water being added.

Figure 9-58. Finishing with excessive mortar slurry.

6.5.6 Evaporation Retardants

Once the finishing operation is completed, measures should be taken to keep the surface from drying before the curing compound is applied. It may take a while for the concrete to set up sufficiently after finishing before the texturing can be performed. This delay may increase if the concrete temperature is cool or a high dosage of a set-retarding admixture is used in the concrete mix.

One method of keeping the surface from drying is the use of an evaporation retardant. The evaporation retardant is applied in a fine mist to uniformly cover the pavement surface. An important property, in addition to reducing evaporation, is that it is specifically formulated to not harm the concrete when final texturing of the surface occurs.

The evaporation retardant (see "DMS-4650, Hydraulic Cement Concrete Curing and Evaporation Retardants") should be applied according to the manufacturer’s recommendation when finishing operations cease and maintained until the final texturing occurs. This may be before or after the carpet drag is performed.

Historically, TxDOT has required the contractor to have a small quantity of evaporation retardant (typically in a small garden-type sprayer) on the project to be used if there was a temporary breakdown of the paving machine or a brief disruption in the delivery of concrete. In these circumstances, the contractor would apply the evaporation retardant to the mass of concrete in front of the paving machine to reduce evaporation and keep a crust from forming on the concrete until paving could resume.