6.7 Curing the Concrete Pavement

Curing is the process by which hydraulic cement concrete matures and develops hardened properties over time as a result of the continued hydration of the cement in the presence of sufficient water and heat. In concrete pavement, the surface area is relatively large compared with the volume. Moisture can be evaporated from this large surface area unless measures are taken to keep the moisture in the concrete. With loss of moisture, the surface concrete will not develop enough strength and could result in scaling, spalling, and other distresses. It is important that proper curing is provided. The most widely used curing method is the use of curing compound.

6.7.1 Curing Compound

Curing compound should meet the requirements of Type 2 membrane curing compound in "DMS-4650, Hydraulic Cement Concrete Curing and Evaporation Retardants." Curing compound is similar to paint and must be thoroughly agitated just before using. The curing compound should not be thinned or diluted. The curing compound should be re-agitated during its use if it becomes non-uniform.

Two separate coats of curing compound are to be applied to all exposed concrete surfaces. Applying the membrane cure in two coats has several advantages over a single coat:

- it results in a thicker film that better resists evaporation,

- it reduces rundown of the curing compound into the tine grooves that might occur in a single heavy coat, and

- it helps ensure a more even coating of the concrete surface if one or more of the spray nozzles were partially obstructed.

The first and second coats should be applied within 10 min. and 30 min. after completing texturing operations, respectively. The individual application rate should be not more than 180 ft.2/gal.

Where the coatings show discontinuities, pinholes, or other defects, or if rain damages the newly applied curing compound, an additional coat of the compound shall be applied.

Once dried, the curing compound will bead water. If the water does not bead but instead wets the surface of the concrete as determined by darkening the concrete, or by visibly soaking into the surface, an additional coat or coats of the curing compound should be applied immediately.

Should the membrane be damaged from any cause before the expiration of 72 hr., the damaged portions should be repaired immediately with additional compound.

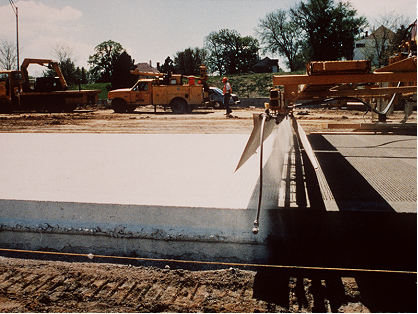

A mechanized spraying unit (see Figure 9-63) is essential when more than one lane of pavement is placed. Note that the machine is applying curing compound to the vertical edge of the concrete as well.

Figure 9-63. Mechanized spraying unit.

Figure 9-64 shows another mechanized unit for spraying curing compound. Note the uniform and complete coverage of the curing compound, even on the side of the concrete.

Figure 9-64. Mechanized spraying unit.

Figure 9-65 illustrates unacceptable application of curing compounds. In this figure, some areas are whiter than others, indicating that curing compound has not been applied uniformly.

Figure 9-65. Unacceptable – non-uniform application of curing compounds.

Plastic shrinkage cracks occurred in the pavement section shown in Figure 9-66 within 5 hr. of concrete placement due to poor curing compound application. This will cause durability problems.

Figure 9-66. Plastic shrinkage cracks.

Figure 9-67 shows that the tie bars have been covered with a plastic sleeve to prevent curing compound from dropping on the tie bars. Any curing compound that ends up on the tie bars or on the “U’s” for the curbs will need to be removed with a steel brush or by sand blasting to ensure proper bonding of the steel to the yet-to-be-placed concrete.

Figure 9-67. Preventing curing compounds from dropping on tie bars.