7.2 Contraction Joints

Contraction joints are used to relieve tensile stresses resulting from temperature drops and moisture variations in concrete. The contraction joints can be longitudinal contraction joints or transverse contraction joints.

A longitudinal contraction joint is required when the concrete placement width is more than 15 ft. because the chances of cracking, in the longitudinal direction, increase. In normal concrete pavement construction, the width of the concrete placement varies and can be as wide as 50 ft. The saw-cut depth of a longitudinal contraction joint should be 1/3 of the slab thickness. For CPCD, single piece tie bars are spaced at 24 in. to keep the two adjoining lanes together. For CRCP, in addition to the transverse steel, single piece tie bars are spaced at 48 in. to keep the two adjoining lanes together.

Transverse contraction joints are used only in plain-jointed pavement (CPCD). An example is shown in Figure 9-69. This type of joint is sawn into the green concrete (concrete will not spall or ravel at the cut edges). CPCD standards require transverse contraction joints to be sawed every 15 ft.

Figure 9-69. Transverse contraction joint.

Dowel bars are provided at the transverse contraction joints to provide load transfer, which reduces deflections and stresses due to wheel load applications. To allow the slabs to move freely in the longitudinal direction due to temperature and moisture variations while providing efficient load transfer, dowel bars are lubricated at least one-half of their length.

The detailed requirements for dowels, such as dowel bar size, length, and spacing, are shown in the CPCD Standards. Figure 9-70 shows a picture of a dowel bar assembly.

Figure 9-70. Dowel bars.

Dowel bars are typically placed in heavy welded wire baskets that hold the bars in proper spacing, depth, and alignment. Full-lane width baskets are typically used, although baskets that are one-half of the lane width have also been used. These wire baskets are shop fabricated. Typically, one end of the dowel bar is tack-welded to the wire basket. The wire basket is nailed to the base to prevent the basket from being pushed along the base once submerged under concrete and under the paving machine.

Alternatively, dowel bars may be mechanically placed by the paving machine. When this method is used, it is important to ensure that the bars are properly aligned and positioned. When this equipment is first used, a few bars should be carefully exposed using a small trowel to verify alignment and positioning. This is done from a work bridge behind the paving machine. Whether wire baskets or mechanical inserters are used, it is extremely important the dowel bars be parallel for the contraction joint to function properly.

Problems can occur when longitudinal and transverse contraction joints are sawn too late or too shallow. Attempts to saw-cut too early might cause raveling of aggregates, while saw-cutting too late might result in uncontrolled cracking. There are a number of factors that determine the optimum time of saw-cutting. They include, but are not limited to, setting characteristics of concrete, ambient and concrete temperatures, and thermal coefficient of concrete. Even though it is possible to theoretically determine the optimum time for saw-cutting, it is almost impossible to do at the job site due to so many variables involved. The best strategy is to saw-cut as early as possible without causing severe raveling. Item 360 allows some minor raveling due to early saw-cutting.

Concrete saws are self-propelled and rotate their blades in a cut-down direction, unlike a handheld circular saw which rotates its blade in a cut-up direction. Most concrete saws use diamond-tipped saw blades which require water to cool and lubricate the blade. Some saws are riding saws, like a riding lawnmower (see Figure 9-71), and others are self-propelled walk-behind saws (see Figure 9-72). Some newer saw models do not require the use of water and can actually saw the concrete earlier than the concrete saws shown here. These saws are typically called “early entry” saws and are specially designed to minimize raveling.

Figure 9-71. Riding saw.

Figure 9-72. Walk-behind saw.

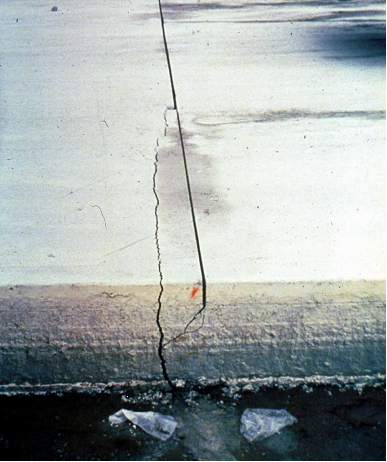

Figure 9-73 shows that the initial saw-cut was being made from the top of the figure to the bottom. For some reason, the initial saw-cutting was delayed. When the saw was halfway across the pavement, the concrete cracked ahead of the saw.

Even if the crack is sealed and allowed to stay in place, the concrete between the crack and the saw-cut will eventually spall out. To prevent uncontrolled cracking, every second or third transverse joint should be sawed first then the intermediate joints. This is called skip-sawing.

Figure 9-73. Uncontrolled crack developed while initial sawing. The left side of the slab needs to be removed and replaced.

Depth of the joints also plays a role in ensuring the proper working of the joints. Shallower cuts than specified will increase the chances of the pavement cracking somewhere else. The saw cut depth must be a minimum of 1/3 of the slab thickness for CPCD pavements and longitudinal contraction joints in single mat CRCP. For longitudinal contraction joints in double mat CRCP, saw cuts are a depth of 4 in. Saw cutting should be accomplished as soon as possible without damaging the pavement, regardless of time of day or weather conditions. Once the saw-cut is completed, it is cleaned and sealant materials are applied. TxDOT’s standard for sealing joints can be found in

Figure 9-74 shows a 12-in. thick pavement with an actual saw-cut depth of approximately 2.5 in. The required saw-cut depth is 4.0 in. As a result of the shallow saw-cut depth, a crack was not induced at the desired joint.

Figure 9-74. Crack was not induced due to shallower saw-cut depth than required.