3.4 Truck-mixed Concrete

In truck-mixed concrete, all of the ingredients are charged directly in the truck mixer. In truck-mixed concrete or “dry batch” operation, as it is sometimes called, the batches are measured by the plant operator and charged from the weigh hoppers directly into the truck mixers for mixing. The plant operator is responsible for accurately batching the concrete in the proper and pre-determined sequence.

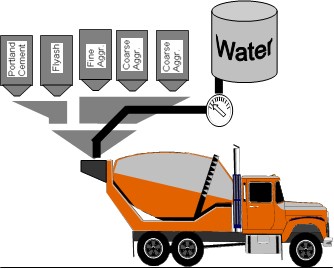

Sequences for charging truck-mixers are more critical than those for central mixers. Figure 9-10 illustrates this process. The first ingredients into the drum are usually a portion of the water and a portion of the coarse aggregate. The water is shut off and aggregates and cementitious materials are ribboned together until all of the cementitious material is in the drum. A final portion of water is added with the last of the aggregates to clean and wash any cementitious material clinging to the hoppers, rear fins, and chutes.

Figure 9-10. Truck-mixed or dry batching of concrete.

One of the problems when the proper batching sequence is not followed is so-called “head packs.” A head pack occurs when sand or sand and cementitious material packs in the head of the drum and remains lodged in the head without being mixed into the concrete. Typically, head packs will be about 12 to 24 in. thick. Head packs are difficult to detect because they break up after approximately half of the concrete has been discharged. Head packs are principally responsible for sand streaks, which occur in the final three-quarters of the discharge.

Once the batching is complete, generally the truck mixer driver completes the mixing in the yard. This allows the driver to examine the mix and determine if it is acceptable prior to leaving the batch plant site. When the mix is correct at the plant, it will most likely be correct when it arrives at the job site.

The truck mixer is equipped with a revolution counter and slump meter as shown in Figure 9-11. The driver is capable of estimating the slump to within 1/2-in. This meter is used for estimating only. The slump is still measured per the project specifications.

Figure 9-11. Slump meter mounted in the mixing truck.

It is necessary to rinse off the rear fins of the mixer between loads and wash and discharge the entire mixer only at the end of the day. Figure 9-12 illustrates the washing of the mixer drum.

Figure 9-12. Washing the mixer drum.

Concrete mixed in a truck mixer is transported to the jobsite at agitating speed. Between each load of concrete, no clumps of concrete should remain on the paddles or fins. Figure 9-13 shows examples of concrete clumps. If concrete is allowed to build up, it will eventually break loose from the drum when a load of concrete is discharged.

Figure 9-13. Large clumps of concrete.