8.5 Material Characterization

For structural design of pavements, an accurate characterization and determination of layer moduli is desired, particularly for flexible pavement design. Pavement layers can be characterized with laboratory testing or field testing.

Laboratory tests can be used to determine the parameters that affect properties of materials, such as moisture susceptibility, stress level, strain amplitude, and the strain rate. The moduli derived from these laboratory tests (triaxial loading, seismic):

- can be either smaller or larger than moduli determined from in situ testing and

- are not compatible with inputs required in FPS 21.

Field tests are more practical and preferred because they can be performed rapidly and may be used to test a large volume of material at multiple project locations in its natural state-of-stress. On the whole, it is more likely the project can be better characterized using field tests rather than relying on the evaluation of samples taken from a few discrete locations.

8.5.1 Laboratory Measurements of Moduli

The common way to develop the stress-strain relationship is through laboratory tests. The most recognized laboratory test method in pavement engineering, especially for flexible pavements, is the resilient modulus (Mr) test.

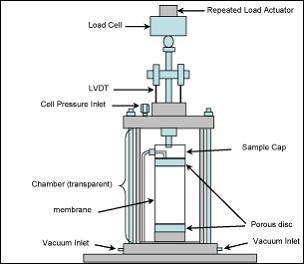

The testing procedure for the resilient modulus consists of subjecting a specimen to a sequence of confining pressure and cyclic deviatoric stress levels. The load pulse consists of a haversine load with a duration of 0.1 sec. loading followed by a rest period of 0.9 sec. Up to 1,000 load cycles may be applied. The load applied to the specimen is monitored by a load cell. The resilient deformation is measured with Linear Variable Differential Transducers (LVDT).

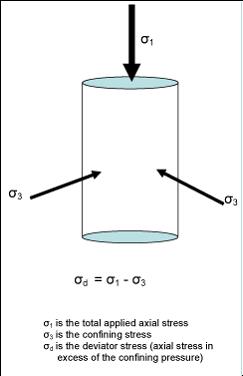

The resilient modulus is the ratio of the repeated axial deviator stress divided by the recovered axial strain. Research is also exploring seismic tools to evaluate modulus of laboratory-prepared samples.

8.5.2 Base and Subgrade Materials

The base and subgrade materials, depending on their gradation and plasticity, can be divided into two groups, fine-grained (cohesive) or coarse-grained (cohesionless or granular). The constitutive properties of both materials are defined based on the state of stress applied to them.

The recommended and simplified constitutive model can be expressed as:

Where:

Mr = resilient modulus

σ

c

and σd

= confining and deviatoric pressure, respectivelyk

1

, k2

, and k3

= coefficients determined from the results of laboratory testsThe model is universally applicable to fine-grained and coarse-grained base and subgrade materials. For unbound materials, AASHTO T 307 is currently used to determine resilient modulus. Sealed latex membranes are placed around the molded triaxial specimens and subsequently placed in a sealed pressure chamber. The specimen and chamber are placed under a loading mechanism in a load frame. Constant confining pressure is applied to the membrane as axial loading is applied in haversine-shaped load pulses. Similar testing can be conducted on bound materials.

8.5.3 Bituminous Mixtures

Modulus of hot-mix asphalt (HMA) can be determined in several ways. The most common laboratory tests are the resilient modulus and the uniaxial frequency sweep.

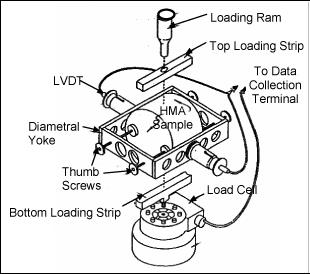

Resilient modulus tests have been used by many researchers to measure the modulus of HMA. These tests can be performed either in compression or diametrically (ASTM D 4123). The following figures illustrate this test method's setup and results. Figure 2-13 shows the resilient modulus testing apparatus. Figure 2-14 shows the stresses applied to a confined specimen. Figure 2-15 shows the resilient modulus test cycle. Figure 2-16 shows the diametrical loading of HMA specimen for modulus testing.

The uniaxial frequency sweep test is very similar to the cyclic triaxial tests. The stresses and strains under sinusoidal loading and varying temperatures and loading frequency are measured and the dynamic modulus is determined. The dynamic modulus is an HMA input parameter in the AASHTOWare Pavement ME design process.

Several parameters affect the modulus of bituminous mixtures. The most important parameters are the rate of loading, temperature, and air void content.

Figure 2-13. Resilient Modulus Testing Apparatus.

Figure 2-14. Stresses acting on a triaxial specimen.

Figure 2-15. Resilient Modulus Test Cycle.

Figure 2-16. Diametrical loading of HMA specimen for modulus testing.

8.5.4 Field-based Measurements of Moduli

Several field-testing methods are available for determining the modulus of a pavement layer. The main methods used are either deflection-based or seismic-based. The falling weight deflectometer (FWD) is the most common field (structural) evaluation device used in Texas. The deflection measurements can be used in backcalculation methods to determine pavement structural layer stiffness, the subgrade elastic modulus, and the depth to stiff layer (bedrock). These are required inputs when using FPS 21 design.

‘Backcalculation’ is a mechanistic evaluation of pavement surface deflection basins generated by various pavement deflection devices. Backcalculation takes a measured surface deflection and attempts to match the value (to within some tolerable error) with a calculated surface deflection generated from an identical pavement structure using assumed layer stiffnesses (moduli).

The assumed layer moduli in the calculated model are adjusted until they produce a surface deflection that closely matches the measured one. The combination of known layer thicknesses and assumed layer stiffnesses that results in this match is then assumed to be near the actual in situ moduli for the various pavement layers.

The backcalculation process is usually iterative and normally run with computer software. Backcalculation guidelines are discussed later in Chapter 5, Section 4 (see “FPS 21 Modulus Inputs and Backcalculation Methodology”), in the manual.

8.5.5 Other Material Characterization Methods

Chapter 4, “Pavement Evaluation,” describes additional field and laboratory methods for characterizing material properties.