7.4 Aggregates

Coarse and fine aggregates make up 60% to 75% of the volume of the concrete mixtures and can have a strong influence on the fresh and hardened properties of the concrete. Almost any aggregate can be used to produce quality concrete provided the aggregates are durable and clean. Item 421 lists the aggregate requirements.

The particle size distribution or gradation of the aggregate is an important characteristic. Coarse aggregate Grades 2 and 3 listed in Item 421 are typically used in concrete pavements and have large nominal maximum aggregate size. Aggregates are typically gap graded, meaning they are missing sizes throughout the distribution. Gap graded aggregates tend to need more paste (cementitious materials and water) to fill the voids between aggregate particles. As the paste content increases, the amount of potential shrinkage also increases. One method to minimize paste content is to optimize the gradation of the aggregates.

7.4.1 Optimizing Aggregate Gradations

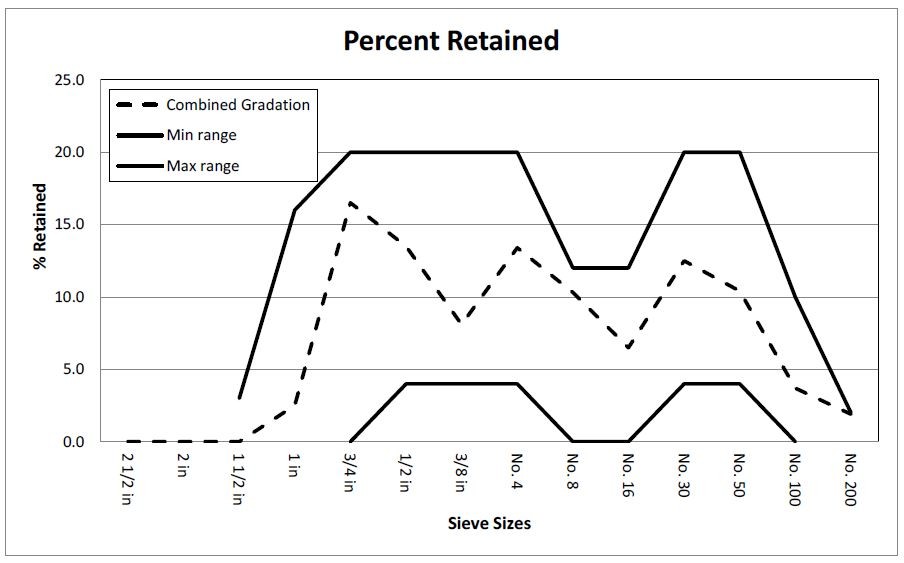

There are several methods that can be utilized to analyze aggregate gradation, and each method has its own pros and cons. The department uses a recently developed percent retained method commonly called the “Tarantula Curve.” In this method, the combined percent retained on every standard sieve for coarse and fine aggregate is used to analyze the gradation. If the percent retained on each sieve is within the limits of the Tarantula Curve, then the gradation is considered optimized. Procedures for analyzing aggregate gradations are outline in Tex-470-A, “Optimized Aggregate Gradation for Hydraulic Cement Concrete Mix Designs.” It is important to note that if an effort is not made to reduce paste content in the mix design, then there are no benefits to utilizing optimized gradation.

Figure 3-6. Percent Retained Chart.

7.4.2 Coefficient of Thermal Expansion of Coarse Aggregates

Since the coarse aggregate makes up the majority of the volume of the concrete, it has a large impact on the coefficient of thermal expansion (CTE) of the overall concrete. The CTE of the concrete influences the long-term performance of CRCP. CRCP sections constructed with concrete having a high CTE value result in shallow spalling at every transverse crack location causing rough ride of the pavement. Through several years of research, it has been determined that if the CTE of the concrete is limited to not more than 5.5 microstrain/°F, the shallow spalling problem was virtually eliminated. Item 360 limits the CTE of concrete used for CRCP to not more than 5.5 microstrain/°F.