2.2 Cold In-place Recycling (Bituminous Layers Only)

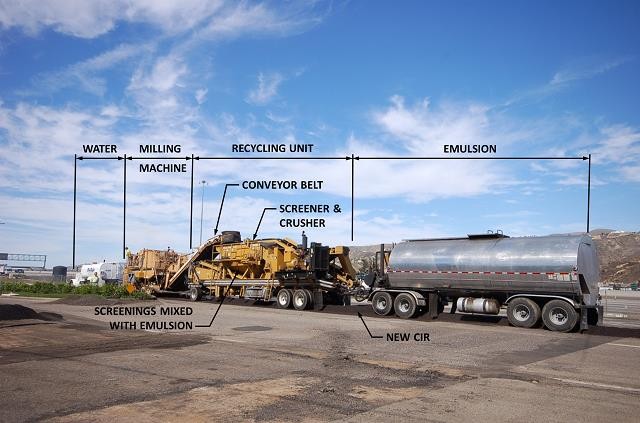

As with the hot in-place process, this rehabilitation technique is meant to address distress within the bituminous portion of the pavement structure, but can reach as deep as 4 to 6 in. Therefore, the base must also be sound, with repairs made to locations that have failed or show potential for failure. The process also involves a specialized train with a cold milling machine, crushing/screen unit, and mixing unit that is capable of reclaiming the old asphalt, crushing (screening and sizing) the RAP, and mixing the RAP with virgin aggregate (if necessary) and emulsion. Figure 7-2 shows a cold in-place recycling train. More recently, foamed asphalt has been used as a binding agent, replacing emulsion on some jobs in other states (Caltrans and others). Other additives, such as lime, fly ash and cement, may be used to improve moisture susceptibility and early strength properties. Coring of the existing ACP surface is necessary to determine the material properties of the existing asphalt pavement to properly design proportions of virgin aggregate, emulsion, and rejuvenator, if necessary. Cores are also inspected for the presence of variations in the pavement layers, delaminations, and whether voids are saturated. The industry does not recommend pavements that have been rutted, heavily patched, or excessively chip-sealed as good candidate projects. Typically, a seal coat or additional overlay will be required after adequate curing since the cold re-processed mix has higher void ratios and is more difficult to compact than hot-mix. Application of this procedure has been addressed through special specifications.

Figure 7-2. Cold In-place Recycling Train.