6.3 Foundation Design

Special attention is required in designing a durable foundation by investigating the underlying soils to determine the appropriate type, level, and depth of stabilization needed. In lieu of subgrade stabilization, a high quality granular base, cement-treated base, or other engineered foundation can be used. Detailed design and construction considerations are provided in Figure 5-5.

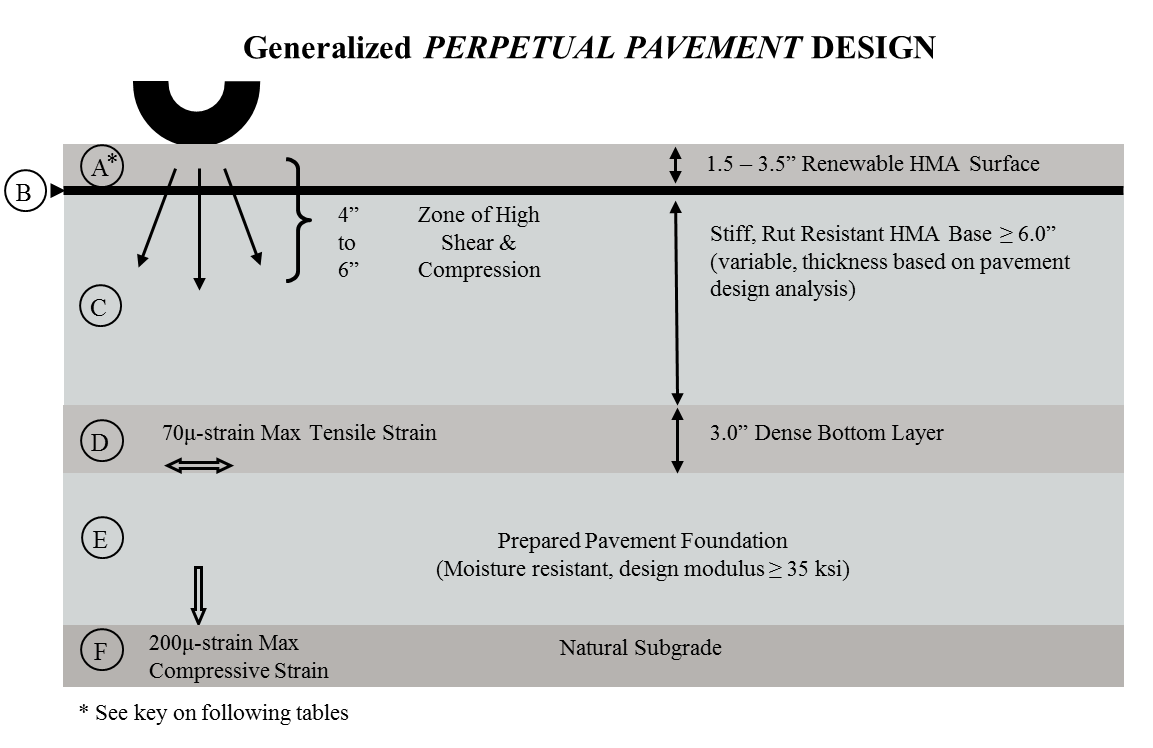

Figure 5-5. Perpetual Pavement Design.

Layer | Layer Composition | Spec Item | Preferred Mix Size | Preferred Lift Thickness | PG Grade | N des |

|---|---|---|---|---|---|---|

A | Renewable surface SMA (or SP) or two-layer system PFC on top of SMA (Passing Balance Mix Design criteria) | Item 342 (PFC Item 346 (SMA) Item 344 (SP) | SMA-D | 1.5 in. 2.0 in. 2.0 in. | 76-XX 76-XX 76-XX | 50 50 50 |

B | Seal Cost | Item 316 or 318 | Grade 4 or 4S | -- | -- | -- |

C | Rut-Resistant HMA Base | Item 344* | SP-B | 4X nominal maximum aggregate size each lift | 70-22** | 50 |

D*** | Dense Bottom Layer | Item 341 | D | 2.0 - 3.0 in. | 64-22 | 35 (SGC); or 97.5% lab density (TGC) |

E | Prepared Pavement Foundation | 1. Item 247 2. Item 275 3. Item 260 4. SS 3003 or SS 3063 | Grade 1/2 Min 200 psi UCS after conditioning Passing Tex 121E Part 1 Passing Test methods 122E or 134E | 6 - 12 in. 6 - 12 in. 8.0 in. 6 - 10 in. | PG 64-22 or CSS 1H | -- |

F | Natural subgrade | -- | -- | -- | -- | -- |

* Preference should be given to designing above the reference zone. Substitution of Item 344 mixtures using Item 341 is permitted after consulting with MNT – Pavement Asset Management. ** Use PG 70-22 or higher grade for all HMA mixes that fall within the top 6.0 in. of the finished pavement surface. *** Can be eliminated if total HMA layer greater than 10 inches thick. See Construction Considerations in figure above, layer E. Must be designed to pass a strength test - contact MTD for details. | ||||||