7.5 Thermal Profiling

Thermal profiles are used to check the level and variability of the mixture temperature behind the paving machine. The applicable test procedure is Tex-244-F. Densification efforts will be impaired if the mixture has cooled below an appropriate compaction temperature (cessation temperature) for the mat thickness and mixture type. Additionally, if there is a lack of temperature uniformity in the mixture caused by thermal or mechanical segregation, excessive paving machine stop time, etc., compactive efforts will be encumbered. Thermal segregation is a known cause of compaction-related density problems that can lead to moisture infiltration and raveling of the mixture. A mat temperature differential behind the paving machine exceeding 25ºF but not exceeding 50ºF is classified as moderate thermal segregation. A mat temperature differential exceeding 50ºF is classified as severe thermal segregation.

7.5.1 Thermal Camera

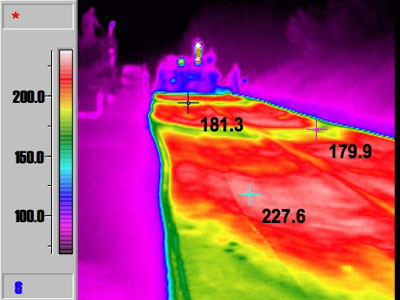

Thermal Camera. A thermal camera records a still shot of the HMA mat temperature distribution directly behind the paving machine (and in front of the rollers). The camera must meet requirements in Tex-244-F and have the ability to display the view’s high and low temperature on an LCD screen. The contractor is required to conduct a thermal profile for each sublot placed over a test section measuring roughly 150 ft. behind the paver. Corrective action must be taken for recurring moderate thermal segregation, and operations must be suspended to eliminate severe thermal segregation (See Fig. 6-42). Areas detected with severe thermal segregation must be evaluated further using the segregation density profile procedure outlined in Tex 207-F.

Figure 6-42. Thermal Camera Image Showing Moderate Thermal Segregation.

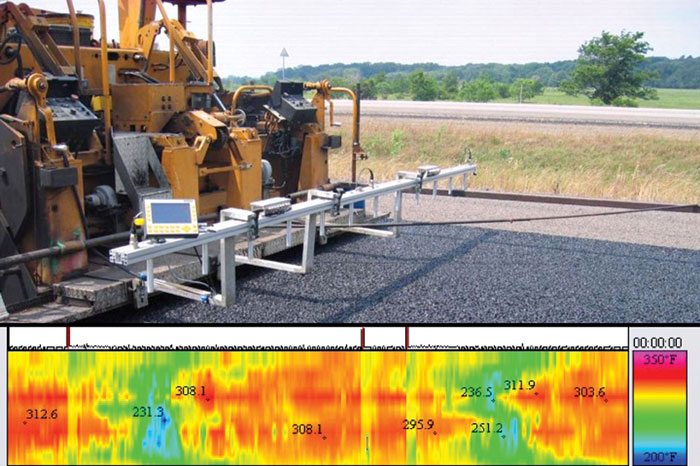

7.5.2 Thermal Imaging System

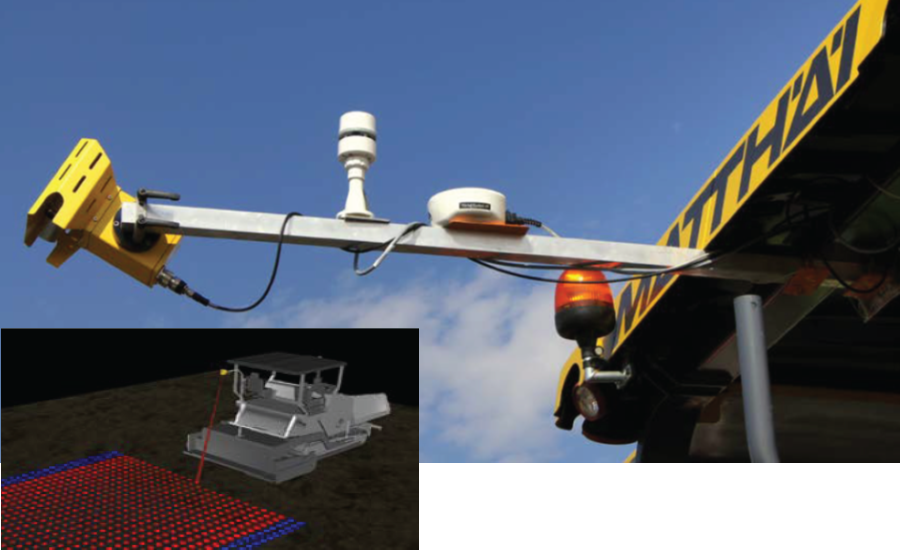

Thermal imaging systems are an innovative advancement in the monitoring of the uniformity of the mixture placement temperature behind the paver screed. The system was developed through TxDOT research and has since been commercialized with additional improvements. Figures 6-43 and 6-44 show an early version of the system and an innovative single scanning IR sensor head system that moves the apparatus away from the low mounting position on the catwalk just behind the screed. The ability to monitor the full-width mat temperature distribution in real-time allows the paving crew to make rapid adjustments to the paving operation that improve the uniformity of the placement temperature, if necessary. An electronic record is generated of the thermal profile tied to longitudinal offset using a distance measuring instrument (DMI) and global positioning system (GPS) coordinates. Electronic copies of the profiles are provided to the engineer; the engineer may suspend operations if the contractor cannot successfully modify the paving process to eliminate recurring severe thermal segregation. Test method Tex-244-F details the apparatus and procedural requirements needed to employ thermal profiling. HMA specifications (Items 341, 342, 344, 346, 347, and 348) offer contractor incentives to use this imaging technique by eliminating the contractor’s requirement to run density profiles (not applicable for Items 347, 348), and by relaxing the placement temperature requirements.

Figure 6-43. Early Version of the Thermal Imaging System.

Figure 6-44. Thermal Profiling Using a Single Scanning Sensor Head (Photo courtesy of MOBA).