7.6 Material Transfer Vehicles (MTVs)

MTVs are used to assist the paver in placing HMA. Most pavers are equipped to receive HMA directly from end dump or live bottom trucks; however, in certain situations, it can be necessary or advantageous to use an MTV. Paving using bottom dump trucks and windrows requires a windrow elevator MTV (see Figure 6-45 and Figure 6-46), while other MTVs are used to provide additional surge volume, which is advantageous because it allows the paver to operate continuously without stopping, minimizes truck waiting time at the paving site and may minimize aggregate segregation and temperature differentials. This subsection covers:

- Windrow elevators

- Surge volume and remixing MTVs.

7.6.1 Windrow Elevators

Windrow elevators are positioned directly in front of pavers and are designed to pick up HMA placed in a windrow and transfer it to the paver hopper. This allows for (1) windrows to be used and (2) virtually continuous paving without stopping. When using windrows and windrow elevators, the windrow laydown rate must match the paver laydown rate. If the amount of material in the windrow is too little or too much, the paver may become overloaded or may run dry and have to stop. To avoid this, windrow paving operations typically have some method (e.g., a loader) available to add or subtract material from the windrow. Some windrow paving operations establish a windrow laydown rate slightly less than the paver laydown rate then periodically add material to the windrow with an end dump truck. Other windrow paving operations leave periodic spaces in the windrow to avoid paver overloading.

Figure 6-45. Windrow paving. © Copyright 2006 University of Washington

Figure 6-46. Windrow Elevator. © Copyright 2006 University of Washington

Other MTVs are used to provide an additional surge volume for the paver (see Figure 6-47, Figure 6-48 and Figure 6-49). This surge volume allows for continuous paver operations. With an MTV, the paver no longer has to stop while one truck leaves and the next truck backs up. Additionally, the MTV serves as a buffer between the paver and the haul trucks, which eliminates most truck bumping problems. Finally, most MTVs offer some sort of remixing capability that remixes the cool HMA crust formed during transport with the hot interior HMA to produce a more uniform mix entering the paver. This remixing can essentially eliminate aggregate segregation and temperature differentials. Some states have actually implemented specifications that require a remixing MTV for paving contracts where segregation and temperature differentials are of concern.

7.6.2 Surge Volume and Remixing MTVs

Surge volume/remixing MTVs are typically used in tandem with a paver hopper insert that increases the capacity of the paver hopper (see Figure 6-50). The insert is removable and sometimes contains remixing apparatus (such as a pugmill) near the bottom. At least one manufacturer has developed a paver solely for use with an MTV. The Roadtec StealthTM paver uses gravity feed and does not contain conveyors, hopper wings, or push rollers, which reduces initial cost as well as maintenance costs (Roadtec, 2001).

Figure 6-47. Blaw Knox MC-30 MTV. © Copyright 2006 University of Washington

Figure 6-48. Cedarapids MS-3 MTV. © Copyright 2006 University of Washington

Figure 6-49. Roadtec Shuttle Buggy MTV. © Copyright 2006 University of Washington

Figure 6-50. Roadtec Shuttle Buggy, front view, showing loading hopper for end dump and live bottom trucks. © Copyright 2006 University of Washington

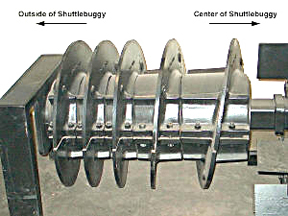

Figure 6-51. Roadtec Shuttle Buggy Patented Remixing Auger. © Copyright 2006 University of Washington

Remixing thoroughness varies from one type of MTV to the next. One idea that seems to work well is the Roadtec Shuttle Buggy patented remixing auger (see Figure 6-51). The auger employs three different pitches that get progressively bigger towards the center of the MTV. This allows for additional material to enter the auger area each time the pitch is increased, resulting in thorough remixing.

In summary, MTVs assist with the transfer of HMA from the transport trucks to the paver. There are two basic types of MTVs:

- windrow elevator MTVs, and

- surge volume/remix MTVs.

Windrow elevator MTVs are used to pick up HMA from a windrow and place it into the paver hopper, while surge volume/remix MTVs provide an additional material surge volume that allows for continuous paving and/or a remix capability that can reduce aggregate/temperature segregation. MTV use costs money and will increase the per ton cost of HMA paving but can help provide superior mat quality. However, MTVs should not be used as a substitute for good production and laydown practices, which are fundamental to good mat quality.