8.6 Roller Variables

There are several variables associated with rollers that can be adjusted from job to job. These variables are:

- sequence and number of rollers,

- roller speed,

- number of roller passes over a given area of the mat,

- location at which each roller works,

- pattern that each roller uses.

Not all these variables are infinitely adjustable, but by adjusting a combination of them. a rolling plan can be developed that will optimize mat compaction.

8.6.1 Compaction Sequence

HMA compaction is typically accomplished by a sequential train of compaction equipment (see Figure 6-60). This allows each piece of equipment to be used only in its most advantageous application, resulting in a higher quality mat (both in density and in smoothness) than could be produced with just a single method of compaction.

Figure 6-60. Breakdown and Intermediate Rollers. © Copyright 2006 University of Washington

A typical compaction train consists of the following (in order of use):

- Screed. The screed is the first device used to compact the mat and may be operated in the vibratory mode.

- Breakdown Roller. The breakdown roller is the first roller behind the screed and, therefore, generally affects the most density gain of any roller in the sequence. Breakdown rollers can be of any type, but are most often vibratory steel wheel and sometimes pneumatic tire.

- Intermediate Roller. The intermediate roller is used behind the breakdown roller if additional compaction is needed. Pneumatic tire rollers are sometimes used as intermediate rollers because they provide a different type of compaction (kneading action) than a breakdown steel wheel vibratory roller. This can help further compact the mat or, at the very least, rearrange the aggregate within the mat to make it receptive to further compaction.

- Finish Roller. The finish roller is last in the sequence and is used to provide a smooth mat surface. Although the finish roller does apply compactive effort, by the time it comes in contact with the mat, the mat may have cooled below cessation temperature. Static steel wheel rollers are almost always used as finishing rollers because they can produce the smoothest surface of any roller type.

- Traffic. After the rollers have compacted the mat to the desired density and produced the desired smoothness, the new pavement is opened to traffic. Traffic loading will provide further compaction in the wheel paths of a finished mat. For instance, a mat compacted to 8% air voids and then opened to heavy traffic (e.g., an interstate freeway) may further compact to about 3 to 5% air voids in the wheel paths over time.

Each position in the roller train (breakdown, intermediate, and finish) may be performed by one roller or several rollers in parallel. For instance, a large paving project may use two vibratory steel wheel rollers for breakdown rolling, one pneumatic tire roller for intermediate rolling, and two static steel wheel rollers for finish rolling. The determination of the best rolling sequence and the number of rollers is generally made on a case-by-case basis and depends upon the desired final air voids, available rollers and their operating parameters, rolling patterns, mix properties, and environmental conditions.

8.6.2 Roller Speed

Rollers are slow; the fastest operating speeds may reach about 11 km/h (7 mph). In order to provide complete and uniform mat compaction, rollers should be operated at a slow, constant speed. Operating at high speeds will reduce compactive effort, while varying roller speed can cause non-uniform compaction. The following table shows typical roller speeds; Item 210 gives typical roller compaction parameters by material type for use on TxDOT jobs.

Type of Roller | Breakdown | Intermediate | Finish |

|---|---|---|---|

Static Steel Wheel | 2.0 – 3.5 mph | 2.5 – 4.0 mph | 3.0 – 5.0 mph |

Pneumatic | 2.0 – 3.5 mph | 2.5 – 4.0 mph | 4.0 – 7.0 mph |

Vibratory Steel Wheel | 2.0 – 3.0 mph | 2.5 – 3.5 mph | not used |

As mentioned previously, roller compactive effort comes in two forms:

- material compression under the surface contact area, and

- shear stress between the compressed area and adjacent uncompressed areas.

Operating at lower speeds allows the roller to remain in contact with a particular mat location longer than it would at higher speeds. This results in more compression per roller pass and, therefore, increases compactive effort. Speed also affects the magnitude of shear stress developed. Lower speeds result in the shearing force between compressed and uncompressed areas being applied for a longer period of time for a particular area (giving a lower shear rate), which results in a higher shear stress. The higher the shear stress, the better able it is to rearrange aggregate into a denser configuration. Therefore, as roller speed decreases, shear stress increases and compactive effort increases.

Because speed affects compactive effort, varying roller speed will vary compactive effort, resulting in uneven compaction. Varying roller speed typically occurs when operators are not closely monitoring their speed or when they speed up to roll an area more quickly so that they can keep pace with the paver. If the mat is being laid down at a faster rate than it can be rolled, the solution should not be to speed up the rollers but rather should involve one of the following options (TRB, 2000):

- Slow down the paver.This may involve adjusting production and material delivery rate as well.

- Use more rollers. Adding rollers can increase the number of roller passes in a given time without reducing the compactive effort per pass.

- Use larger, wider rollers. Wider rollers allow greater coverage per pass.

Finally, rollers should not be stopped on a fresh mat because they can cause large indentations that are difficult, if not impossible, to remove.

Roller speed directly affects compactive effort. The best compactive effort and most uniform densities are achieved by slow, consistent roller speeds. If rollers cannot keep up with the pace of the paving operation, they should not be operated at higher speeds because this reduces compactive effort. Rather, the paving operation should be slowed or more/larger rollers should be used.

8.6.3 Number of Roller Passes

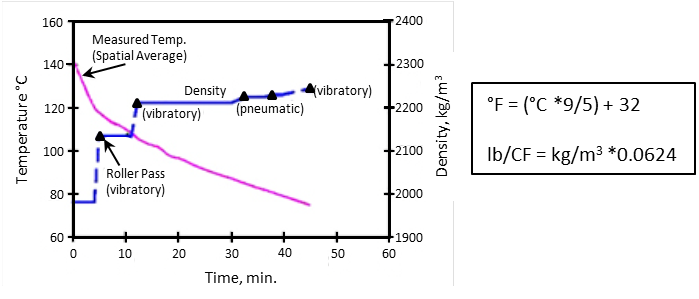

Generally, it takes more than one roller pass over a particular area to achieve satisfactory compaction. A roller pass over a specific mat area is defined as one complete trip over the area in question by the entire roller. This means that if the roller uses two steel drums, both drums must travel over the area in question to make “one pass.” In general, earlier passes over hotter HMA will increase density (decrease air voids) more than later passes over cooler HMA (see Figure 6-61).

Supporting Data: Graph and data taken from Chadbourn et al. (1998). |

|

Figure 6-61. Density and Measured Mat Temperature vs. Time (note the increase in density for each roller pass) (Chadbourn et al., 1998). © Copyright 2006 University of Washington

- Test Strip

- Contractors will often (and are sometimes required to) construct a “test strip” to help determine the necessary number of passes.

- A test strip is a small section of mat laid out at the beginning of a project with the purpose of determining the best roller type, sequence, number of passes, and rolling pattern to use.

- Intelligent Compaction (IC). To date, the benefit of using IC for HMA lifts has been more related to uniform coverage by mapping number of desired passes than any contribution in meeting density. This is because current IC systems lack the necessary sensitivity to distinguish incremental benefit to improving density in typical relatively thin HMA lifts.

8.6.4 Rolling Location

Determining where the different rollers in the train should physically be is actually a question of mat temperature and roller characteristics and not one of physical distance. 'Compaction Sequence' under

described the roller sequence and its reasoning while this section describes some more general rules-of-thumb.

In general, the greatest compaction per roller pass can be achieved directly behind the paver because the mat is the hottest and least viscous in that position. Therefore, the breakdown roller(s) should operate as close to the paver as possible to achieve the most compaction per roller pass. Likewise, the intermediate roller(s) and finish roller(s) should be placed on the mat at a safe distance from the roller in front of them and begin rolling as soon as possible. Sometimes, when a tender mix is placed, these general rules do not apply.

8.6.5 Roller Pattern

The roller pattern combines roller sequence, speed, number of passes, and location to provide complete coverage of the entire mat in such a manner that results in:

- uniform compaction to a specified level of air voids,

- acceptable surface smoothness, and

- complete compaction before cessation temperature is reached.

Uniform compaction depends on getting the same number of roller passes over each area of the mat. This means that a pattern must be developed that covers the entire mat with an equal number of roller passes from each type of roller. For example, if two vibratory steel wheel rollers are operating as the breakdown rollers, they must work together so each portion of the mat receives the same number of passes. Since they are the same type of roller, it is not necessary for each roller to cover the entire mat. If two different rollers, such as a vibratory steel wheel roller and a pneumatic tire roller, are performing breakdown rolling, each roller should cover the entire mat an equal number of times, otherwise compaction may be non-uniform. Although roller patterns can vary widely, some general rules-of-thumb are:

- Overlap between two successive passes should be at least 15 cm (6 in.) (Roberts et al., 1996; Ingersoll-Rand, 2001). This ensures that small steering inaccuracies do not leave gaps between successive passes.

- The roller should be turned slightly to the side when reversing directions or stopping. Rollers tend to create a slight bow hump when moving and will leave this hump in place when reversing directions or stopping. Often, it is difficult to flatten out this hump on subsequent passes if it is perpendicular to the direction of roller travel. By turning the roller slightly before changing direction or stopping, the resulting hump will be diagonal to the direction of roller travel and easier to flatten out with subsequent passes. However, hard steering should be avoided because it can tear or shove the mat.

- Roller passes should end at different points to prevent developing a hump (caused by the direction change) that spans the entire transverse length of the mat.

- Where there is an unconfined edge on the mat, the first roller pass should stay about 0.15 – 0.30 m (0.5 – 1 ft.) away from the mat edge. The small resultant strip of uncompacted mat helps confine the rest of the mat and minimize lateral displacement near mat edges. This strip should then be compacted on the next roller pass (Ingersoll-Rand, 2001).

- Do not roll over a designed crown in the road. Rolling over a crown will flatten it out.

- When compacting a longitudinal joint, the first roller pass should be entirely on the hot mat about 0.15 – 0.30 m (0.5 – 1 ft.) away from the joint. On subsequent passes, the roller should travel mostly on the newly constructed mat and only overlap the older mat by about 0.15 m (0.5 ft.) (Roberts et al., 1996; Ingersoll-Rand, 2001).

- Joints should be compacted with the roller operating parallel to the joint. Although transverse joints cannot always be compacted this way, perpendicular rolling does not compact the hot/new side as well.

- For steel wheeled rollers, operate the powered wheel on the paver side. This will minimize humps that can be caused by the drive wheel.

The above guidelines are just general rules of thumb; other methods may work. However, without a clear roller pattern, the center of a lane typically receives more roller passes than the outsides. This is of particular concern because most wheel loads occur nearer the edges of any particular lane in the wheel paths. In summary, any method that achieves uniform coverage, acceptable density, and acceptable smoothness without damaging the mat can be considered a good method.