2.3.1 LAMP Development Process

This section describes the process of developing a LAMP, establishes the elements of the plan, and provides an example that can be used to develop plans for urban and rural corridors.

shows the steps in developing a LAMP. The steps are explained in detail below.

Step Number | Task |

Step 1 | Use LAA Statement developed during LAA |

Step 2 | Develop design guidelines to guide development of the corridor |

Step 3 | Divide the corridor into development zones |

Step 1: Utilizing the LAA

The LAA provides a comprehensive picture of the existing land uses facing the designer. No matter the scope of the project or the stage of the design process, an assessment of some type must be performed to ensure that important issues are not overlooked. In this step, the designer uses the LAA to address key design considerations identified within the corridor. This may include (but not be limited to):

- Views to be preserved;

- Significant landscape/trees to be preserved;

- Areas to be screened;

- Best locations for sound walls;

- Best locations for landscape plantings;

- Problem maintenance areas;

- Key off-site relationships and interactions; and

- Sites requiring environmental mitigation or protection.

Once a designer has determined the best approach for meeting specific design goals, the process proceeds to the development of design refinement in Step 2.

Step 2: Develop Design Guidelines for the Corridor

The simplest form of a LAMP is a list of design detail palettes. These guidelines provide maximum design flexibility while ensuring harmony among the basic design elements described in other sections of this manual.

To guide the design of a transportation facility with respect to its landscape and aesthetics properties, there are five palettes within a basic LAMP Tool Kit:

- Materials color palette;

- Materials finish palette;

- Signage and fixtures palette;

- Structural systems and details palette; and

- Plant materials palette.

A materials table organizes the selections made from the five palettes listed above.

Materials Color Palette

Standard building materials are typically neutral in hues, though not all hues are complimentary. It is very important to coordinate the colors of materials used within a project. In so far as possible, all structures placed on the roadside or incorporated into the pavement surface, signage, and other appurtenances should take advantage of natural color and avoid the use of any finish requiring routine maintenance or replacement.

For example, painted surfaces should be avoided wherever possible. The color palette within the guidelines should list the material along with the source and the color name provided by that source (if available).

Materials Finish Palette

Finishes are also related to the natural color of the material. In the context of landscape and aesthetics design, finish has to do with the textural quality of the surface or any special surface treatment, such as vandal resistant finishes or sandblasting.

Signage and Fixtures Palette

The palette would include, but not be limited to fencing, sign supports, guardrail supports, hardscape finishes below guardrails, delineators, crash barriers, rail terminators, luminaires, poles, and signals. These are small items but should coordinate with the major design components to ensure a harmonious composition.

Structural Systems and Elements Palette

This palette catalogues the elements that will be used for a variety of structures. It lists the considerations that would not necessarily be covered in the Materials Color palette, Materials Finish palette, or the Signage and Fixtures palette. For example, there are a variety of panel shapes that can be used for reinforced earth retaining walls as well as for the wall cap and termination. Likewise, the finish on materials such as concrete masonry units (CMU), segmented retaining wall (SRW) blocks, and walks can vary widely. Other elements that might be included are bent shapes and reveals, beam reveals, bent ends and connection types, special bridge rails and CTB, head and end wall railings, pedestrian separation railings, treatment of median voids, under bridge surfaces, and traffic channelization islands.

This section of the corridor plan requires a great deal of coordination between bridge, roadway, signs and signals, and environmental personnel. This section could be a simple table or may involve a more detailed catalog of design options based on the appropriate development zone. The concept of development zone is elaborated in Step 3.

Materials Table

A materials table organizes the selections made from the four palettes discussed above. A materials table may be used to view many different elements at one time and allows the designer to consider aesthetics issues for the corridor as a whole, rather than on a piece-by-piece basis. The list of elements shown in the materials table (MATTBL) is for example purposes.

The final list will vary with the project. The list should include as many elements as possible even if the element will be a generic type. This prompts comparison between these and elements that might be treated specially. In addition to the items already listed, other elements for consideration might include:

- Delineators;

- Crash barrier;

- Rail terminator;

- Signals and supports;

- Signs and sign supports;

- Bridge types;

- Abutment protection;

- Bent ends;

- Reinforced earth walls and cap;

- Medians and gores;

- Medians w/drainage section;

- Bridge rails;

- Guard rails;

- Noise walls;

- Sign bridge, vertical and horizontal;

- Sign mounting hardware; and

- Riprap.

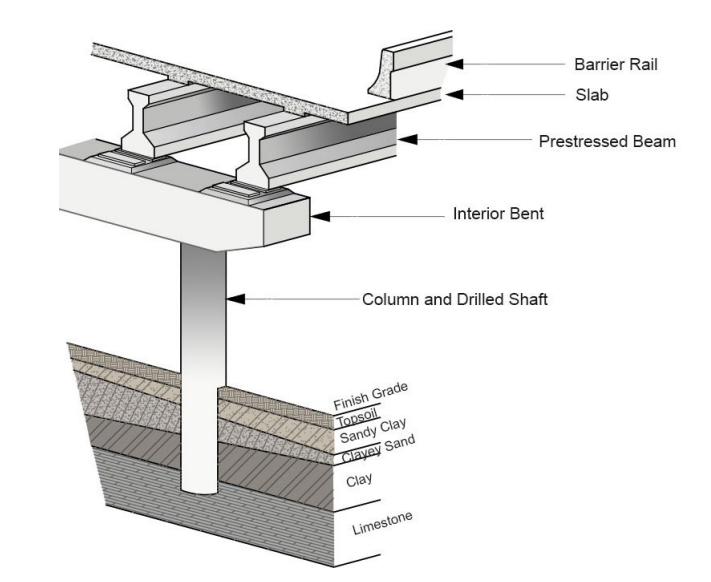

See

for a description of different bridge components.

Figure 2-6: Bridge Aesthetic Components

Plant Materials Palette

Plant materials should be divided into two sections. The first section would have recommendations for basic erosion control as well as appropriate landscape enhancements for the purpose of minimizing maintenance and ensuring a safe, sustainable roadside. The second section should specify proposed plant materials for ornamental purposes in cases where special interests or adjacent communities wish to partner with TxDOT for long term maintenance.

Step 3: Divide the Corridor into Development Zones

The application of the corridor LAMP will coordinate development to satisfy landscape and aesthetic concerns and ensure coordination with the natural and built elements of the highway.

This development zone concept is a key to ensuring the long-term sustainability of a highway corridor

. A development zone is a classification of the highway corridor that reflects the anticipated levels of intensity and character of landscape development. This includes all structures, pavement, and planted ROW maintained by TxDOT. After issues of safety have been addressed, the primary consideration as to the ultimate feasibility of a project will be the level of maintenance it will require to function as it is intended. The level of development is related directly to the department resources required for long-term maintenance, a combination of available funds and the pool of expertise available through the contracting and inspection process.Three zone types are defined, which represent three different levels of development (see

). This is an element-based approach that uses the estimated development and maintenance considerations of structures, planting, surface treatment, mowing, and access to classify the project. The first two zones include ornamental landscape enhancements and require a community partner to assume responsibility for long-term maintenance. Zone III has no ornamental enhancements. All planting and other materials are used to reestablish native or adapted vegetation associations to achieve long-term erosion control and sustainability of the corridor.

This approach does not precisely quantify maintenance costs but does enable the designer to recommend preliminary resource allocation regarding maintenance levels and maintenance locations. The calculation of more accurate maintenance costs for any specific project will be performed as part of the site-design process.

Zone I – High Maintenance

Zone I has intensive development requiring frequent or intense landscape maintenance. Almost any type of structure and/or surface treatments may be in a Zone I development. All Zone I development is limited to projects where a public entity contracts with TxDOT to assume responsibility for all maintenance, except the pavement and associated structures.

Zone I development is generally discouraged on all state ROW due to the extreme maintenance requirements. Before a public entity is allowed to develop a ROW to this level, TxDOT should be satisfied that the entity seeking the partnership has the experience and wherewithal to maintain the development at an appropriate level and that the proposed development will in no way threaten the public health or safety.

- Structures:Zone I development usually involves an interchange or intersection. For this reason, there are often bridges, channelization islands, signs, lighting standards, and other types of structures that must be considered as part of the project.

- Plant material:Projects will have a significant budget devoted to the installation of ornamental plant materials (shrubs, groundcover, annuals, and perennials) and a percentage of the non-paved areas devoted to ornamental planting. These areas also contain large quantities of prepared soil and mulch, require mechanical weed removal and/or the use of selective herbicides, and irrigation.

- Plant bed areas:In Zone I projects, bed areas are subject to weed and grass invasion. Maintenance of the beds requires frequent edging.

- Irrigation:Any landscape development that requires continuous/scheduled irrigation of plant materials is a Zone I development.

- Mowing:Zone I includes any project requiring frequent mowing cycles to maintain a manicured appearance, or projects with irregular shapes that require the use of small push-type or riding mowing machinery.

- Access:Access may be limited, and special equipment may be needed to remove refuse or to maintain plants.

Zone II – Medium Maintenance

This zone limits the types and placement of plant material and the length of time in which routine maintenance will be required. Maintenance activities for plants in this zone may be intermittent, perhaps only once per year or two years.

- Bed preparation:No bed planting which requires the wholesale disturbance of the soil, either in tilling or the adding of soil amendments, except under special circumstances, (such as mass reforestation tree planting) shall be included in Zone II. Shrubs used in rows or as mass plantings shall be planted in individual planting pits. Preparation of planting areas shall be limited to mowing or herbicide application of existing vegetation.

- Plant material:Trees and shrubs used in Zone II shall be those with significantly low maintenance requirements and must be placed in areas where their full mature size can be attained without pruning. Shrubs shall be those species which are rapid growers, evergreen or fast-growing perennials that are greater than 4 ft tall and are able to effectively shade out weed seedlings beneath them once established. No plant in Zone II will require pruning to maintain a specific shape or character. Plants requiring routine insect control or fertilization beyond establishment should not be used.

- Weed control:Weeding required in Zone II (after the plant establishment period) shall be limited to the use of mechanical or herbicide treatments of structure edges or tree-wells only. No hand weeding shall be required.

- Irrigation:Irrigation shall be limited to drip or bubbler systems with automatic controllers. Temporary irrigation systems with shrub risers are allowed. No turf irrigation shall be used.

Zone III – Low Maintenance

This zone includes landscape elements or treatments that require little or no long-term increase in maintenance.

- Plant material:Plant material in Zone III shall be limited to the use of tree plantings within areas not included in regular mowing cycles. Shrubs shall be used primarily to reduce or improve maintenance within a site. Only those plant species of demonstrated hardiness for the roadside shall be used. No insect control, supplemental fertilization, or pruning is anticipated for the life of the project.

- Weed control:Weeding required in Zone III shall be limited to the use of herbicide treatments of tree-wells or shrub plantings for a short period only to enhance establishment. No later weed control is anticipated for the life of the planting.

- Irrigation:Irrigation shall be limited to the use of truck irrigation only. No continuous, long-term irrigation is anticipated after the establishment period.

- Access:Planting included in Zone III shall not be placed near any structures or obstacles in such a way that normal mowing operations shall be affected.