Traffic Safety

Cross-drainage and longitudinal drainage facilities are usually necessary in any highway project to relieve drainage from the natural phenomenon of runoff to the highway. However, due to their inherent mass and fixed nature, they can pose somewhat of a safety threat to errant vehicles and associated drivers and passengers.

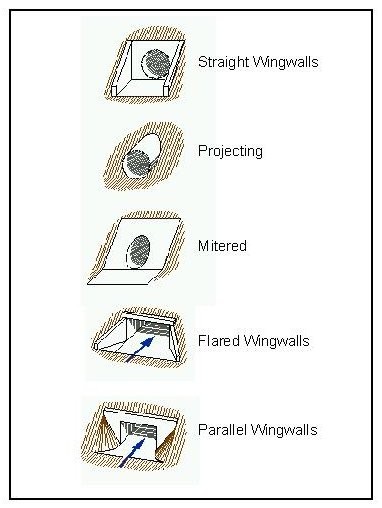

Figure 8-2 shows sketches of various end treatment types. The Bridge Division maintains standard details of culvert end treatments. For requirements and applications, see the Roadway Design Manual.

Figure 8-2. Typical Culvert End Treatments

Safety end treatment (SET) of a culvert provides a method of mitigating a less safe condition without interfering with the hydraulic function of the culvert. SETs such as those used with driveway and other small diameter culverts may be more hydraulically efficient by providing both tapered wingwalls and a beveled edge instead of using a mitered section. SETs for larger culverts that are not protected by a railing or guard fence use pipe runners arranged either horizontally or vertically.

Figure 8-3. Pipe mitered to conform to fill slope.

Figure 8-4. Pipe mitired to conform to fill slope.

Figure 8-5. End section conforming to fill slope

Figure 8-6. End section conforming to fill slope with pipe runners

Shielding by metal beam guard fence is a traditional protection method and has proven to be very effective in terms of safety. However, metal beam guard fence also can be more expensive than safety end treatment.

Generally, if clear zone requirements can be met, neither safety end treatment nor protection such as guard fence is necessary. However, some site conditions may still warrant such measures. See the Design Clear Zone Requirements in the

for more information.