Design Criteria for Specific Wall Types

Spread Footing Walls

Provide expansion joints at intervals not exceeding 96 feet and contraction joints at intervals not exceeding 32 feet.

MSE Walls

Evaluate MSE walls for total and differential settlement for all applicable dead and live load combinations at Service I limit states in accordance with AASHTO LRFD Bridge Design Specifications. Total settlement should be less than 4 inches unless approved by the TxDOT State Geotechnical Engineer. Limit differential settlement as defined in the AASHTO LRFD Bridge Design Specifications, C11.10.4.1-1. Slip joints may be required to limit effects of differential settlement.

Temporary MSE or Welded Wire Face Wall

If the site condition soil properties differ from those indicated above, then the RW(TEW) standard will need to be modified to reflect the actual site soil properties.

Set the minimum earth reinforcement length to 6 ft. To ensure proper performance of the wall in place, evaluate project-specific requirements for wall backfill type, wall embedment, wall drainage, conflicts within the wall reinforced zone, and other considerations as necessary. Give special consideration to walls that are subject to inundation. Type C backfill is the default backfill for temporary walls. Specify Type D backfill for walls that are subject to inundation. Analyze walls subject to inundation for 3 ft. of draw-down. Backfill the 2-ft. zone immediately behind the facing with clean coarse rock or cement-stabilized backfill. A designer who prefers to use coarse rock or cement-stabilized backfill must state this in the plan documents.

If a temporary MSE wall will be in service for longer than 3 years, the designer must state this in the plan documents to ensure that the wall supplier provides a design with an adequate service life. Temporary MSE walls placed adjacent to permanent MSE walls must be detailed with earth reinforcement that will prevent corrosion of the permanent earth reinforcements due to contact of dissimilar metals. This may be accomplished by providing galvanized or synthetic earth reinforcements for the temporary MSE walls.

Standard specification Items 403 and 423 govern construction of this wall type.

Concrete Block Walls

If the site condition soil properties differ from those indicated above then the RW(CB) standard needs to be modified to reflect the actual site soil properties.

Concrete block walls may be classified as either structural or landscape walls. The minimum strap length varies depending on the wall function. Minimum earth reinforcement lengths are 6-ft. for walls designated as landscape walls, and 8-ft. otherwise. To ensure proper performance of the wall in place, evaluate project-specific requirements for wall backfill type, wall embedment, wall drainage, conflicts within the wall reinforced zone, and other considerations as necessary. Type BS backfill is the default for permanent walls. Give special consideration to walls that are subject to inundation. Specify Type DS backfill and analyze these walls for 3 ft. of draw-down. The maximum particle size of the select backfill is limited to ¾" for nonmetallic reinforcements. Consult the RW(CB) and RW(CB)DD standard drawing for guidance on wall definition and design. Standard specification Item 423 governs the design and construction of this wall type.

Tied-Back Walls

Soil Nailed Walls

Evaluate soil corrosion for permanent walls per AASHTO LRFD Bridge Design Specifications Article 11.12.8, use the following minimum criteria:

- Hole diameter — 6 in.

- Bar size — #6

- Grade — 75 ksi for permanent walls

- Bars — epoxy-coated or galvanized, Dywidag or Williams threadbar, or equivalent

Standard specification Item 423 Retaining Walls and Item 410 Soil Nail Anchor govern construction of this wall type.

Ensure that nails have a minimum 6-in. clearance from any obstructions. Obtain permanent easements for nails that cross the right-of-way line. The top of the wall should be no more than 2 ft. above existing grade to ensure constructability of the soil nail wall; special design considerations are required when this distance is exceeded. Nail spacing depends on project-specific site and loading conditions. A 3-ft. to 4.5-ft. vertical spacing and a 3.0-ft. to 4.5-ft. horizontal spacing is typical. Soil strengths used in the design of soil nail walls are typically determined from correlations of strength to Standard Penetration Test values conducted through the embankment to be nailed. Use nominal strengths in the analysis. Design walls considering the proposed wall geometry and loading. Limit head strength to avoid an unbalanced design. Unrealistic or high head strength results in shorter nails and causes the lowest nails to carry a disproportionate amount of load.Final verification on design should include a global (overall) check using the analysis mode of the design program used or an independent slope-stability program that is capable of modeling soil nail anchors. Consider equipment accessibility due to horizontal and vertical clearance restrictions.

Rock Nailed Walls

Consider the distance the rock nails will project behind the wall and any potential conflicts with subsurface obstructions or right of way limitations. Ensure that nails have a minimum 6-in. clear cover from any obstructions. Obtain permanent easements for nails that cross the right-of-way line. Locate the top of wall no more than 2 ft. above existing grade to ensure constructability of the rock nail wall; special design considerations are required when this distance is exceeded. Consider equipment accessibility due to horizontal and vertical clearance restrictions.

Drilled Shaft Walls

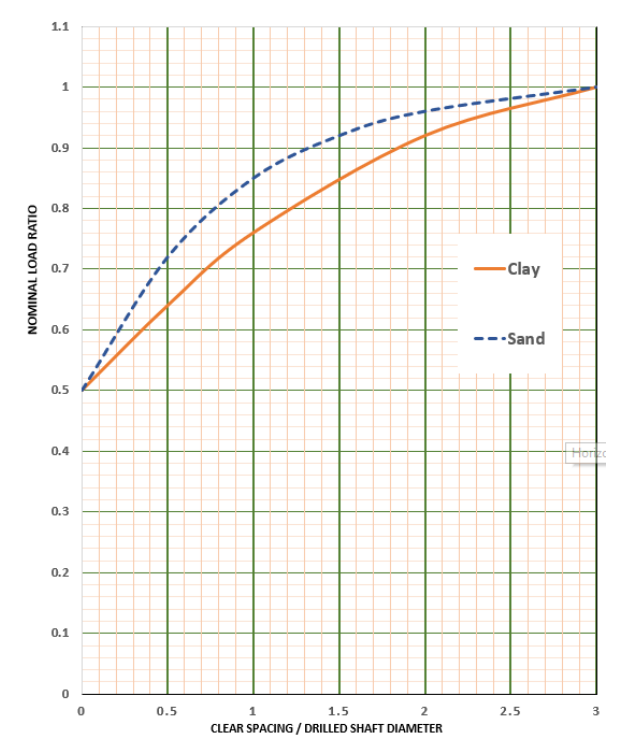

- Reduction based on close shaft spacing (per AASHTO LRFD Article 10.8.3.6), refer to reduction within the following Figure 6-1.

- Reduction of surface soil strength based on expected swelling/softening of the soil

Figure 6–1. Nominal Load Ratio vs. Clear Spacing/Drilled Shaft Diameter

Design the walls iteratively, varying the length of shaft for successive runs. Make a plot of shaft embedment versus top of shaft deflection to determine when additional embedment does not result in a reduced deflection. The minimum embedment length that results in no additional top of shaft deflection is defined as the depth to fixity. An acceptable approach is to terminate the shaft at a depth 33% longer than minimum embedded depth to fixity. Maximum tolerable top of shaft deflection is set at 1% of the exposed wall height. The maximum steel reinforcement within concrete is 2.5% to 3% as limited by reinforcing spacing requirements. Minimum clear spacing between adjacent shafts is set at 1 ft. Design wall fascia to account for the maximum earth pressure at the bottom of the wall. The load applied to the fascia shall be applied through the window between the shafts assuming simple supports at the centerline of the shafts. The Contractor is responsible to ensure that face stability is maintained between shafts throughout construction. Address this by a note in the plans. Consider equipment accessibility due to horizontal and vertical clearance restrictions. Standard specification Item 416 Drilled Shafts and Item 423 Retaining Walls govern construction of this wall type and are supported by special specification Prefabricated Soil Drainage Mat.

Sheet Piles and Soldier Pile Walls