Chapter 2: Investigations

Section 1: Subsurface Investigations

Overview

Conduct subsurface investigations for projects containing the following features:

- Bridges

- Retaining walls

- Slopes and embankments

- Sign structures

- Illumination

- Sound walls

- Radio towers

Perform minimum required testing as noted in the following section, including Standard Penetration Tests (SPT), Shelby Tube samples, Rock Quality Designation, and percent recovery.

Review of Existing Data

Review all existing data before determining new data requirements. Old bridge plans are a common source of this information. Old borings contain information that can be used to determine geotechnical testing approach.

Boring Location

The complexity and variability of geological conditions and the type, length, and width of a structure determine the number of borings required for foundation exploration. Except as noted here, follow AASHTO LRFD Bridge Design Specifications Article 10.4.2 as a starting point to determine the locations and depths of borings.

When developing boring location plan, consider structure type, estimated loading, and foundation geometry. Locate the borings in a feasible and accessible area. When determining the location of borings, always avoid overhead power lines and underground utilities. If possible, avoid steep slopes and standing or flowing water. Deviations within a 20-ft. radius of the staked location are not usually excessive but note these deviations on the logs and obtain the correct surface elevation.

When determining the location and depth of borings, carefully consider the following factors:

- Boring depth

- Lowering of gradeline

- Embankment

- Cuts over 5 feet

- Channel relocations and channel widenings

- Potential or observed environmental contamination of soil or groundwater

- Scour

- Foundation loads

- Foundation type

Bridges

Boring Locations and Spacing

- Two test holes minimum per bridge

- Test holes must be located 100 ft or less from the anticipated center of each bent/substructure and each abutment

- Test holes must be located 50 ft or less from the anticipated center of any monoshafts used on the bridge

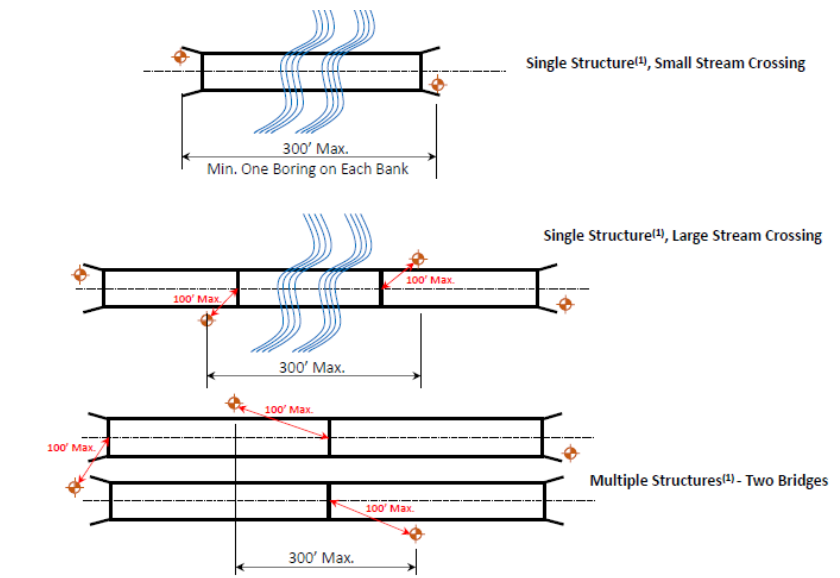

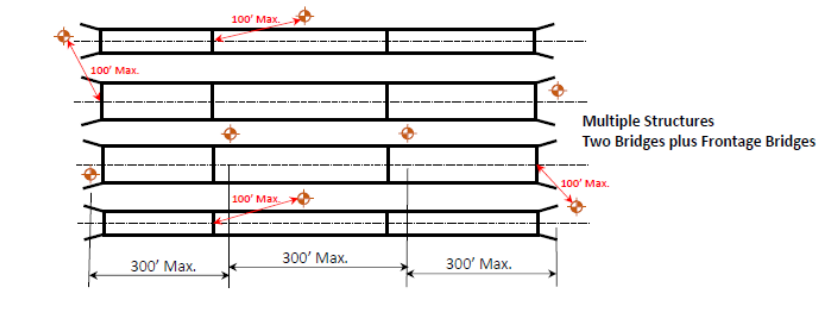

- Do not space test holes greater than 300 ft. apart along the bridge centerlineTest holes from adjacent bridges can be used to fulfill the above criteria, granted they are deep enough and collect sufficient sampling information and results. Feature(s) being bridged or beneath the deck are inconsequential to location and spacing criteria. Access and right of way issues occur on any project and are reason to offset borings but contact Geotechnical Branch for major deviations to the above criteria or AASHTO LRFD Article 10.4.2. The following figures display example boring location plans for common types of bridge structures.

Note (1): The transverse effect of test holes as shown may not be as critical as it for Multiple Structures with wide separation (e.g., >300 ft between bridges). The holes may be placed all along one side of the structures or directly along centerline of proposed roadway. Consult with Geotechnical Branch for more guidelines.

Figure 2–1. Minimum number of test holes for common types of structures

Boring Depth

anticipated loading

, or the results of previous or legacy TCP tests and correlation graphs. When SPT data is used to judge probable founding or tip elevations, consider elevations where SPT refusal occurred in the legacy borings. Consider the need for borings with depths greater than 20 ft. below the anticipated tip elevations for foundations on major structures or other cases of high or unusual loading conditions.Depending on the strength of the geomaterial estimated from the SPT blow counts and Rock Quality Designation (RQD) during the drilling operation, it may be necessary to adjust the termination depth of borings from the planned depths. Engineering decisions of early termination of borings and/or extending borings beyond the planned depths shall be made by a competent geotechnical engineer based on realtime SPT blow counts and RQD. Typically, drill deep enough until one of the following conditions are met:

- In non-water crossings and minor stream crossings, early termination of the boring depth at no shallower than 60 feet when drilling within bedrock when 25ft of continuous core within moderately weathered to nonweathered, hard to very hard rock had been recovered.

- In major stream crossings, rivers, and lake crossings, early termination of the boring depth at no shallower than 80 ft when drilling within bedrock when 40ft of continuous core within moderately weathered to nonweathered, hard to very hard rock had been recovered.

Stream Crossings

Major stream crossings require borings in the channel if no existing data is available. A site inspection by the driller or logger is necessary to evaluate site accessibility and special equipment needs.

Karst Features

Grade Separations

Bridge Field Exploration

- Boring spacing. Space borings near each abutment of the proposed structure plus enough intermediate borings to determine the depth and location of all significant soil and rock strata. If a reasonable correlation between boring and testing information (for example, SPT data, Pocket Penetrometer results, stratigraphy) cannot be made, consult with the design engineer to determine the need for additional borings.

- Soil sampling and testing. Conduct Standard Penetration tests (SPT) in accordance with AASHTO T 206 or ASTM D1586 every 5-ft. interval beginning at 5-ft depth from the surface. Where cohesive soils are observed collect thin-walled Shelby Tube samples in accordance with AASHTO T 207 or ASTM D1587 at the intermediate locations between SPT samples. Rock core drilling and sampling should be performed in accordance with AASHTO T 225.

- Near surface soil layer test. Test soft near surface soil layers (0 to 20 feet) as directed under the subsection in this chapter titled Slopes and Embankments.

- Soil and bedrock classification. Complete soil and bedrock classification and log record for each boring on the logs in accordance with Chapter 4, Soil and Bed Rock Logging.

- Ground water. Include ground water elevation measurements (including date of measurement) as part of the data acquisition. Obtain an additional groundwater elevation minimum 15 minutes after the initial encounter. Site conditions or the design objectives may require installation of piezometers to establish a long-term or steady state ground water conditions.

Retaining Walls

Obtain soil borings for walls carrying a traffic surcharge or any wall taller than 5 ft. Evaluate need for soil borings for walls shorter than 5 ft. on a case-by-case basis. For short-term conditions in cohesive soilsuse undrained shear strength determined using laboratory strength tests on undisturbed Shelby tube samples for design analysis. Strength measurement from pocket penetrometer tests and hand torvanes should not be solely used to evaluate undrained shear strength except as supplement to other laboratory strength tests on undisturbed tube samples. Within cohesionless material, SPT can be used to evaluate the internal friction angle but is not intended to supersede results from direct shear testing. A more rigorous sampling and testing program may be required for long-term evaluation of walls founded on cohesive soils.

Boring Locations and Spacing

Boring Depth for Fill Walls

Boring Depth for Cut Walls

Cantilever walls, including drilled shaft walls and sheet pile walls, require the depth of borings to extend beyond the anticipated depth of the shaft below the cut, which is typically between one and two times the height of the wall.

Soil Samples and Testing

Ground Water

Other Structures

Conduct foundation investigations for high-mast illumination, radio towers, and overhead sign structures as close as feasibly possible when other borings are not located nearby.

The typical depth of the borings ranges from 30 to 70 ft. but depends on existing and proposed ground lines, soil strength, and structure loading.

Concrete sound (noise) walls require drilled shaft foundation design that results in shafts 20 to 30ft embedded and spaced 10 to 25ft center to center along the wall alignment. When adjacent structure borings are not present, place soundwall borings at maximum 200ft intervals and to a depth of 40 to 50ft depending on soil strength and anticipated planned height of soundwall.

Slopes and Embankments

Soil Borings

The exploration should include the following:

- The soil under future embankments. Advance borings to a minimum depth below existing grade equal to the height of the embankment or 20 ft., whichever is greater. If compressible soils exist extend the foundation soil boring considering height, width, and loading of embankment. Conduct Standard Penetration tests (SPT) in accordance with AASHTO T 206 or ASTM D1586 every 5-ft. interval beginning at 5-ft depth from the surface. Where cohesive soils are observed collect thin-walled Shelby Tube samples in accordance with AASHTO T 207 or ASTM D1587 at the intermediate locations between SPT samples.

- Soil in proposed cuts. Advance borings to a minimum depth of 15 ft. below the bottom of the proposed cut. Conduct Standard Penetration tests (SPT) in accordance with AASHTO T 206 or ASTM D1586 every 5-ft. interval beginning at 5-ft depth from the surface. Where cohesive soils are observed collect thin-walled Shelby Tube samples in accordance with AASHTO T 207 or ASTM D1587 at the intermediate locations between SPT samples.

- Ground water elevation measurements. Include ground water elevation measurements (including date of measurement) as part of the data acquisition for slopes and embankments. Obtain an additional groundwater elevation at a minimum of 15 minutes after the initial encounter. Site conditions or the design objective may require the installation of piezometers to establish a longterm or steady state ground water conditions.

Soil Testing

- Short-term conditions. In cohesive soils, use undrained shear strength determined using laboratory strength tests on undisturbed Shelby tube samples for design. Strength measurement from pocket penetrometer tests, hand torvanes, or field vane shear tests should not be solely used to evaluate undrained shear strength except as a supplement to laboratory strength tests on undisturbed tube samples. Avoid correlations of undrained shear strength based on SPT tests. Use unconfined compression tests, unconsolidated undrained (UU) triaxial tests, consolidated undrained (CU) and/or direct shear tests.

- Long-term conditions. Use consolidated undrained (CU) triaxial tests with pore pressure measurement and/or drained direct shear tests.

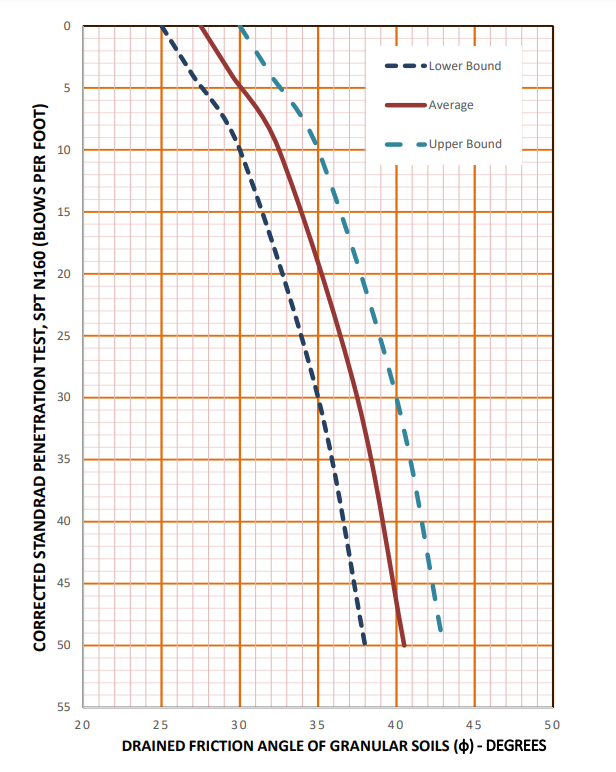

Estimation of long-term effective stress friction angle of clay soils based on published correlations with index properties of the soil is acceptable. Correlations between corrected SPT blow counts to drained angle of internal friction for granular soils presented in AASHTO LRFD Bridge Design Specifications Table 10.4.6.2.4-1 may be used, and a graphical representation is presented in Figure 2-2. However, the selection of specific values in the range may require experience and care. For cohesive soils, published PI correlations from Atterberg results proven to yield reasonable estimates of effective friction angle may be used.

For cuts with high plasticity clays exposed to weathering or cyclic wetting and drying, long-term shear strength reduction due to soil relaxation may be possible. For such instances a reduction in shear strength as appropriate to account for shear strength loss due to weathering and long-term relaxation should be considered in the evaluation of long-term stability of embankments or slopes.

Figure 2–2. SPT vs. Angle of Internal Friction for Cohesionless Soils