Glass Bead Application Properties

During field striping applications, beads are applied either by spraying (pressure drop) or dropping (gravity drop) onto the wet marking material. Retroreflectivity can be controlled to some degree by drop-on bead application procedures.

Important:

The two most important field-controlled properties that require on-site inspection are:- the amount and dispersion of exposed beads across a line

- the depth of embedment of the beads.

Separate discussions of these properties follow.

Table 3-4 summarizes some problems that have been encountered during glass bead application and potential remedies of those problems.

Trips | Tips |

|---|---|

Concentration of beads on one side |

|

Concentration of beads in middle of line |

|

Using excessive amounts of beads |

|

Beads are buried in material |

|

Beads are partially covered with material (thin-film binders only) |

|

Beads are not imbedded sufficiently |

|

Surging pattern of beads |

|

Excessive amount of beads off the material and on the pavement |

|

Amount and Dispersion of Beads.

Inspection of bead coverage across the marking is necessary to assure uniform retroreflectivity across the surface of the marking. In general, the more beads on a surface, the greater the retroreflectivity, although too many beads may cause retroreflectivity to decrease.Glass bead dispersion may be visually checked by close-up visual examination or by the sun-over-shoulder method described in Test Method

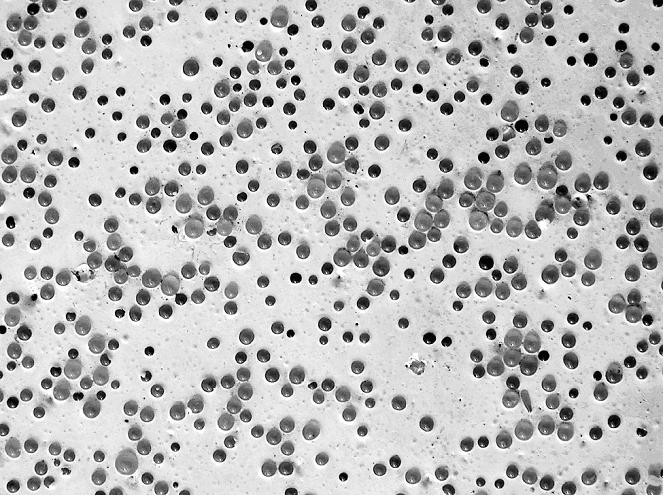

. Beads should be uniformly applied over the surface of the markings. If they appear otherwise, notify the operator that his bead gun or pump is likely not functioning properly. Figure 3-3 shows an example of a thermoplastic stripe with well-dispersed glass beads.

Figure 3-3. Good glass-bead dispersion for Type III beads in thermoplastic.

When placing a thin-film marking (i.e., water-based paint, epoxy, and other thin-film materials), inspectors should ensure that beads are not “rolling” when dropped onto a marking, which often occurs when the striping truck is traveling faster than 10 mph. When beads roll through a wet thin-film marking material, they become coated with binder, making them useless as retroreflectors.

Bead Embedment Depth.

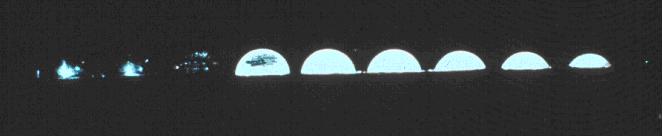

Bead depth can be estimated by close-up visual examination. Beads should be embedded into the pavement marking material at 60 percent of the bead diameter for maximum retroreflective performance. Because the material that is “behind” the bead is the actual image that is reflected back to the driver, it is important that proper embedment depth is achieved. Figure 3-4 shows the effect of bead embedment depth on retroreflectivity.

Figure 3-4. Effect of bead embedment depth on retroreflectivity.

clearly shows that beads not embedded deeply enough will cause the light to be reflected in many directions instead of back to the driver, greatly reducing the retroreflectivity. In addition, beads that are under embedded will be easily worn away after very little traffic wear. Beads that are embedded too deep will still reflect light, but not as much. Therefore, if errors in embedment are made, it is better for the beads to be too deep than too shallow, as can be observed in Figure 3-4.

During the striping operation, if the beads appear to be too high or too low, notify the operator to make adjustments. In the case of hot-applied materials, such as thermoplastic, the material temperature has a major effect on bead embedment. The pressure of the bead applicator also affects bead embedment.