Factors of Aggregate Affecting Performance

Maximum Particle Size and Gradation

It is desirable that aggregates used for seal coats and surface treatments consist of essentially one size of aggregate. If all of the aggregate particles are about the same size, embedment depth will be the same for each particle contributing to successful performance of the seal coat. Very fine aggregate particles are likely to become submerged in the asphalt. For practical purposes, specifications allow some oversize and some undersize particles. TxDOT Standard Specification Item 302,

, describes the size and gradation requirements for aggregates used in seal coats and surface treatments.

The maximum particle size refers to the largest size allowable. For example, according to the specification, a Grade 3 aggregate has a maximum particle size of 5/8 inch, and a Grade 4 has a maximum particle size of ½ inch. A successful seal coat is more generally achieved when larger size cover aggregate is employed. This is because the larger aggregates are less sensitive to small variations in binder application rate than when smaller cover aggregates are used. Larger size aggregates, however, also tend to create more tire/pavement noise and are more likely to cause vehicle damage when dislodged from the pavement.

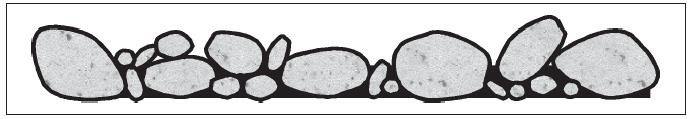

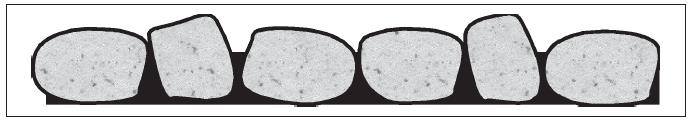

a. Graded aggregates make it difficult to achieve consistent embedment depth.�

(b) Single size gradation produces consistent results.�

Figure 3-4. Gradation comparisons�

Cleanliness.

If aggregate is excessively dirty or dusty, asphalt binder will not be able to hold the aggregate particles securely in place. The asphalt will stick to the coating of dirt or dust, and with traffic the aggregate particles will dislodge. The aggregate must also be free of foreign matter such as leaves, grass, sticks, and lumps of clay or dirt. Cleanliness is measured by the Deleterious Material Test (Tex-217-F, Part I) and the Decantation Test (Tex-406-A).Shape.

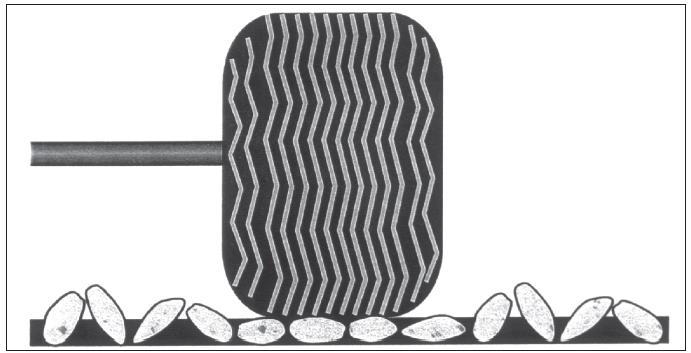

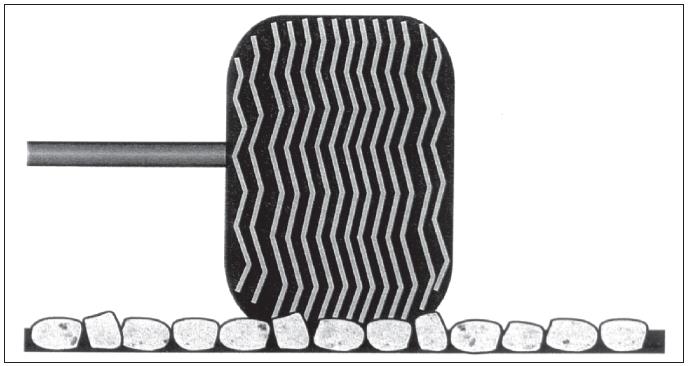

The ideal shape of aggregate particles for seal coats and surface treatments is a shape that is as near to cubical as possible. When the seal coat aggregate is in place, traffic gradually orients the particles until each is lying on its flattest side with its thinnest dimension generally perpendicular to the roadway surface. (Figure 3-5).

Figure 3-5. Effect of aggregate shape.�

The average thickness of the seal coat when the aggregate particles attain this ultimate position is equal to the overall average of the thinnest dimensions of the stone particles. This overall average of the smallest dimensions of the particles is referred to as its Average Least Dimension (ALD). This ALD is important for two reasons:

- It can control the quantity of cover stone and asphalt binder that should be applied.

- ALD values can differ widely for any given maximum aggregate size due to particle shape.

The ALD will be discussed in more detail in Chapter 4. TxDOT specifications (Item 302,

Aggregates for Surface Treatments

) refer to the Flakiness Index, as measured in Test Method Tex-224-F, to control the aggregate shape. The lower the Flakiness Index, the more cubical the aggregate is.Angularity is also an important shape characteristic (Figure 3-6). The more angular the stone, the better the interlocking because there are many points of contact. Angularity for crushed gravel is measured by the Coarse Aggregate Angularity Test (Tex-460-A, Part I).

0% Crushed / 100% with 2 or more crushed faces�

Figure 3-6 Percent crushed fragments in gravels.�

Toughness.

The aggregate must be able to resist abrasion and degradation. If the aggregate surfaces degrade under traffic, particles may break apart, broken pieces may dislodge (causing windshield damage), and flushing will likely result. These aggregate properties are measured by the Los Angeles Abrasion Test (Test Method Tex-410-A) and Magnesium Sulfate Soundness Loss (Test Method Tex-411-A).Aggregate Absorption (uncoated).

All aggregates are somewhat porous and will absorb water as well as asphalt. Limestone and lightweight aggregates are more absorptive than aggregates such as gravel. The amount of binder applied to the roadway should compensate for absorption into the cover aggregate. More absorptive aggregates also tend to have a higher affinity for asphalt (adhere better to the asphalt binder).When aggregates are used that have a lower affinity for asphalt, extra care should be taken with respect to dryness and cleanliness of the aggregate, dry roadway surface, and dry weather.

Figure 3-6. Aggregate before and after Los Angeles Abrasion test.�