3.5 Existing Surface Preparation for Overlays

Overlays make up a large portion of the roadway paving done today. The degree of surface preparation for an overlay is dependent on the condition and type of the existing pavement. The existing pavement should be structurally sound, level, clean and capable of bonding to the overlay. To meet these prerequisites, the existing pavement is usually repaired, leveled (by milling, applying a level-up course or both), cleaned, and then coated with a binding agent. This subsection covers:

- repair,

- tack coats.

3.5.1 Repair

Generally, pavement overlays are used to restore surface course functional characteristics (smoothness, friction, and aesthetics) or add structural support to an existing pavement. However, even a structural overlay should be placed on a structurally sound base. If an existing pavement is cracked or provides inadequate structural support, these defects will eventually reflect through even the best-constructed overlay and cause premature pavement failure in the form of cracks and deformations. To maximize an overlay’s useful life, failed sections of the existing pavements should be patched or replaced and existing pavement cracks should be filled.

Figure 6-2. Repairing Failed Pavement Sections before Overlay.

At most, overlays are designed to add only some structural support; the remaining structural support must reside in the existing pavement. Therefore, small areas of localized structural failure in the existing pavement should be repaired or replaced to provide this structural support (see Figure 6-2). Often, existing pavement failure may be caused by inadequate subgrade or flex base support, or poor drainage. In these cases, the existing pavement over the failed area should be removed full depth and the subgrade should be prepared as it would be for a new pavement (Item 351, “Flexible Pavement Structure Repair”).

Existing pavement crack repair methods depend upon the type and severity of cracks. Badly cracked pavement sections, especially those with pattern cracking (e.g., fatigue cracking) must be patched or replaced because these distresses are often symptoms of more extensive base or subgrade structural failure. Existing cracks other than those symptomatic of structural failure should be cleaned out (blown out with pressurized air and/or swept) and filled with a crack-sealing material when the cracks are clean and dry. Cracks less than about 3/8 in. in width may be too narrow for crack-sealing material to enter. These narrow cracks can be widened with a mechanical router before sealing. Swelling of crack sealant may occur particularly under newly placed thin HMA overlays, causing a bump at these locations. Use of WMA with their lower placement temperatures may mitigate this problem.

If the existing pavement has an excessive amount of fine cracks but is still structurally adequate, it may be more economical to apply a seal coat or slurry/scrub seal instead of filling each individual crack. Also, these situations may lend themselves to using a spray-paver where a relatively heavy emulsion is applied concurrently with the overlay.

In summary, pavement repair should be extensive enough to provide an existing pavement with adequate structural support. Pavement management techniques should provide for overlays before an existing pavement has lost most or all of its structural support capability.

3.5.2 Tack Coats

A tack coat material can be a PG binder or an emulsion layer applied between HMA pavement lifts to promote bonding. Adequate bonding between constructed lifts (especially between the existing road surface and an overlay) is critical for the constructed pavement structure to behave as a single unit and provide adequate strength. If adjacent layers do not bond to one another, they essentially behave as multiple independent thin layers − none of which are designed to accommodate the anticipated traffic-imposed bending or near surface shear stresses. Inadequate bonding between layers can result in delamination (debonding) followed by longitudinal wheel path cracking, alligator cracking, potholes, and other distresses, such as rutting, that greatly reduce pavement life.

3.5.2.1 Application

Tack coats should be applied uniformly across the entire pavement surface and result in more than about 90% surface coverage. In order for this uniformity to be consistently achieved, all aspects of the application must be considered and carefully controlled. Specific aspects are:

- the condition of the pavement surface receiving the tack coat,

- the application rate, and

- the type of tack coat according to standard TxDOT specifications on Item 330, “Limestone Rock Asphalt Pavement,” and hot-mix items 334, 340, 341, 342, 344, 346, and 347.

3.5.2.2 Condition of the Pavement Surface Receiving the Tack Coat

The pavement surface receiving the tack coat should be clean and dry to promote maximum bonding. Emulsified tack coat materials may be applied to cool and/or damp pavement; however, the length of time needed for the set to occur may increase. Since existing and milled pavements can be quite dirty and dusty, their surfaces should be cleaned off by sweeping or washing before any tack coat is placed, otherwise the tack coat material may bond to the dirt and dust rather than the adjacent pavement layers. This can result in excessive tracking of the tack coat material. Construction vehicles and equipment pick up the tack-dirt mixture on their tires and leave the existing roadway with little or no tack coat in the wheel paths (see Figure 6-3). Slippage cracking and delamination are distresses typically seen when cleanliness is lacking.

Figure 6-3. Tack coat tracking resulting in no tack coat in the wheel path. © Copyright 2006 University of Washington

3.5.2.3 Application Rate

Tack coat application should result in a thin, uniform coating of tack coat material covering approximately 90% of the pavement surface (Flexible Pavements of Ohio, 2001). To achieve this result, application rate will vary based on the condition of the pavement receiving the tack coat. Too little tack coat can result in inadequate bonding between layers. Too much tack coat can create a lubricated slippage plane between layers or can cause the tack coat material to be drawn into an overlay, negatively affecting mix properties and even creating a potential for bleeding in thin overlays (Flexible Pavements of Ohio, 2001). Table 6-1 shows recommended application rates from Flexible Pavements of Ohio (2001.)

Existing Pavement Condition | Application Rate (gal/SY) | |

|---|---|---|

Residual a | Undiluted b | |

New HMA | 0.03 - 0.04 | 0.05 - 0.07 |

Oxidized HMA | 0.04 - 0.06 | 0.07 - 0.10 |

Milled HMA | 0.06 - 0.08 | 0.10 - 0.13 |

Milled PCC | 0.06 - 0.08 | 0.10 - 0.13 |

PCC | 0.04 - 0.06 | 0.07 - 0.10 |

a Residual: The application rate of just the asphalt binder content of the emulsion.b Undiluted: The application rate of the Undiluted emulsion. | ||

Basic application rate considerations are:

- Roughness of the pavement surface receiving the tack coat. Rough surfaces require more tack coat than smooth surfaces. For instance, milling produces a rough, grooved surface, which will increase the existing pavement’s surface area when compared to an ungrooved surface. The surface area increase is dependent on the type, number, condition, and spacing of cutting drum teeth, but is typically in the range of 20 to 30%, which requires a corresponding increase in tack coat (20 to 30% more) when compared to an unmilled surface (TRB, 2000).

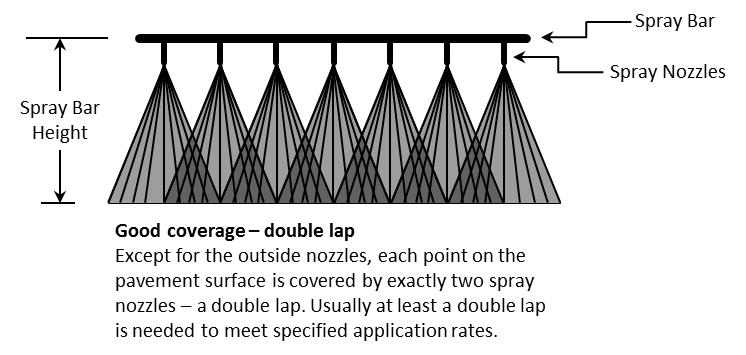

- Distributor vehicle. Several vehicle-related adjustments and settings are critical to achieving uniform tack coat placement. Essentially, the nozzle patterns, spray bar height, and distribution pressure must work together to produce uniform tack coat application. Generally, the best applications result from a "double lap" or "triple lap" coverage. "Double/triple lap" means that the nozzle spray patterns overlap one another such that every portion of the pavement receives spray from exactly two/three nozzles (see Figure 6-4, Figure 6-5, Figure 6-6, Figure 6-7, Figure 6-8, Figure 6-9, and Figure 6-10). Specific guidance follows:

- Nozzle spray patterns should be identical to one another along a distributor spray bar. Differing coverages will result in streaks and gaps in the tack coat.

- Spray bar height should remain constant. As tack coat is applied, the vehicle will become lighter, causing the spray bar to rise. The tack coat application vehicle should be able to compensate for this. Excessively low spray bars result in streaks, while excessively high spray bars cause excessive nozzle overlap, resulting in an excessive application rate.

- Pressure within the distributor must be capable of forcing the tack coat material out the spray nozzles at a constant rate. Inconsistent pressure will result in non-uniform application rates.

- Temperature within the distributor should be maintained between 24°C (75°F) and 54°C (130°F). Excessive heating may cause the emulsion to break while still in the distributor.

Figure 6-4. Tack coat application using double lap coverage. © Copyright 2006 University of Washington

Figure 6-5. Tack Coat Distributor Truck. © Copyright 2006 University of Washington

Figure 6-6. Tack Coat Distributor Truck Spray Bar. © Copyright 2006 University of Washington

Figure 6-7. Tack Coat Distributor Control Panel. © Copyright 2006 University of Washington

Figure 6-8. Jet dryer used ahead of the tack coat distributor. © Copyright 2006 University of Washington

Figure 6-9. Tack coat application. © Copyright 2006 University of Washington

Figure 6-10. Tack coat application showing nozzle coverage area. © Copyright 2006 University of Washington

3.5.3 Other Tack Coat Aspects

3.5.3.1 Timing

Generally, a tack coat should be allowed enough time to break and set (emulsion) before applying the next layer of hot-mix asphalt (HMA).

3.5.3.2 Tracking

Tracking is the pick-up of tack coat material by vehicle tires. Tracking deposits tack coat material on adjacent pavement surfaces. Although this material is unsightly, it generally has little effect and wears away quickly. In extreme cases, tracking may deposit enough tack coat material to distort pavement surfaces or hinder a driver's ability to navigate (Flexible Pavements of Ohio, 2001). Rubberized tack coats have an especially high propensity to stick to vehicle tires. More critical to long-term pavement performance is that any tack removed by tracking from construction or other vehicular traffic implies that the tack is no longer available to stick the new overlay to the existing surface. This can become extremely critical in cases of HMA delivery trucks tracking tack out of the wheel paths while in the process of their delivery in front of the paving machine. This sets up the worst possible scenario of removing tack from the most critical part of the pavement structure directly subject to the shearing action of traffic wheel loads. Allowing tack coats to set (emulsions) before driving on them can substantially reduce tracking. Also, new “trackless” emulsion products that dry very quickly, but are reactivated by the heat of the newly placed HMA, are worth consideration when tracking may be an issue.

Generally, traffic should not be allowed on tack coats. When a tacked road surface is exposed to traffic, the potential exists for reduced skid resistance, especially during wet weather (Flexible Pavements of Ohio, 2001). When tack coat surfaces must be opened to traffic, they should be covered with sand to provide friction and prevent pick-up. A typical rate for applying a sand cover is 4 to 8 lb./SY (Flexible Pavements of Ohio, 2001).